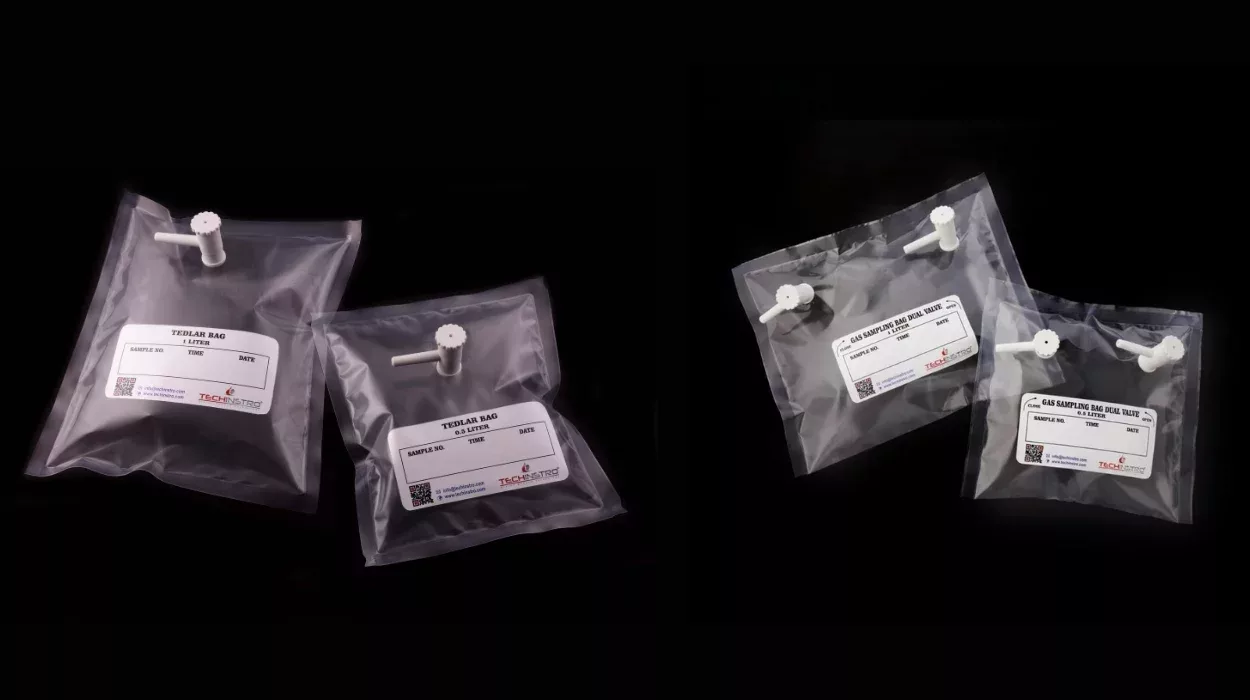

Gas sampling bags are essential for collecting and analyzing gas samples in various industries, including environmental monitoring, industrial hygiene, and scientific research. Among the many types of gas sampling bags available, Tedlar bags and dual valve bags are two common options.

What are Tedlar Bags?

Tedlar bags are made from polyvinyl fluoride (PVF) plastic. They are widely used because they are durable, flexible, and can hold a many gases without reacting with them. Tedlar bags are popular in environmental monitoring and industrial applications where accurate gas sampling is crucial.

Key Features of Tedlar Bags:

- Durable Material: Tedlar is tough and can withstand rough handling.

- Chemical Resistance: It doesn’t react with most gases, ensuring accurate samples.

- Single Valve: Tedlar bags typically have one valve for filling and extracting the gas sample.

List of Tedlar Bag Manufacturing Companies:

You can order tedlar bags through the following links:

What are Dual Valve Bags?

Dual-valve bags, on the other hand, are gas sampling bags equipped with two valves: an inlet and an outlet. These bags can be made from various materials, including Tedlar, but what sets them apart is their dual-valve design.

Key Features of Dual Valve Bags:

- Two Valves: One valve fills the bag with the gas sample, and the other is used to extract the gas for analysis.

- Convenient Sampling: The dual-valve design makes filling and emptying the bag easier without contaminating the sample.

- Variety of Materials: Dual valve bags can be made from different materials, including Tedlar, Mylar, and more.

Main Differences Between Tedlar Bags and Dual Valve Bags

1. Number of Valves:

- Tedlar Bags: Typically have one valve.

- Dual Valve Bags: Have two valves (one for filling and one for emptying).

2. Ease of Use:

- Tedlar Bags: With one valve, avoiding contamination when filling and emptying the bag can be slightly more challenging.

- Dual Valve Bags: These are easier to use because the separate valves prevent contamination during sampling and analysis.

3. Material:

- Tedlar Bags: Made specifically from Tedlar (PVF), known for its durability and chemical resistance.

- Dual Valve Bags: These can be made from various materials, including Tedlar, but the defining feature is the dual valves.

4. Applications:

- Tedlar Bags: Ideal for general gas sampling needs, especially when handling chemically reactive gases.

- Dual Valve Bags: These are useful when contamination control is critical and ease of filling and emptying is important.

Choosing the Right Bag for Your Needs

When deciding between Tedlar bags and dual valve bags, consider the following factors:

- Type of Gas: If you need to sample gases that are chemically reactive, Tedlar bags are a great choice because of their chemical resistance.

- Sampling Process: If you require a more straightforward and contamination-free sampling process, dual valve bags are preferable.

- Material Preference: If you prefer a specific material due to durability or other properties, check the availability of that material in dual valve designs.

Conclusion

Both Tedlar bags and dual valve bags have their unique advantages. Tedlar bags are known for their durability and chemical resistance, which makes them a reliable choice for many gas sampling applications. Dual valve bags, with their two-valve design, offer ease of use and better contamination control. By understanding the differences and considering your specific needs, you can choose the right gas sampling bag for your application.