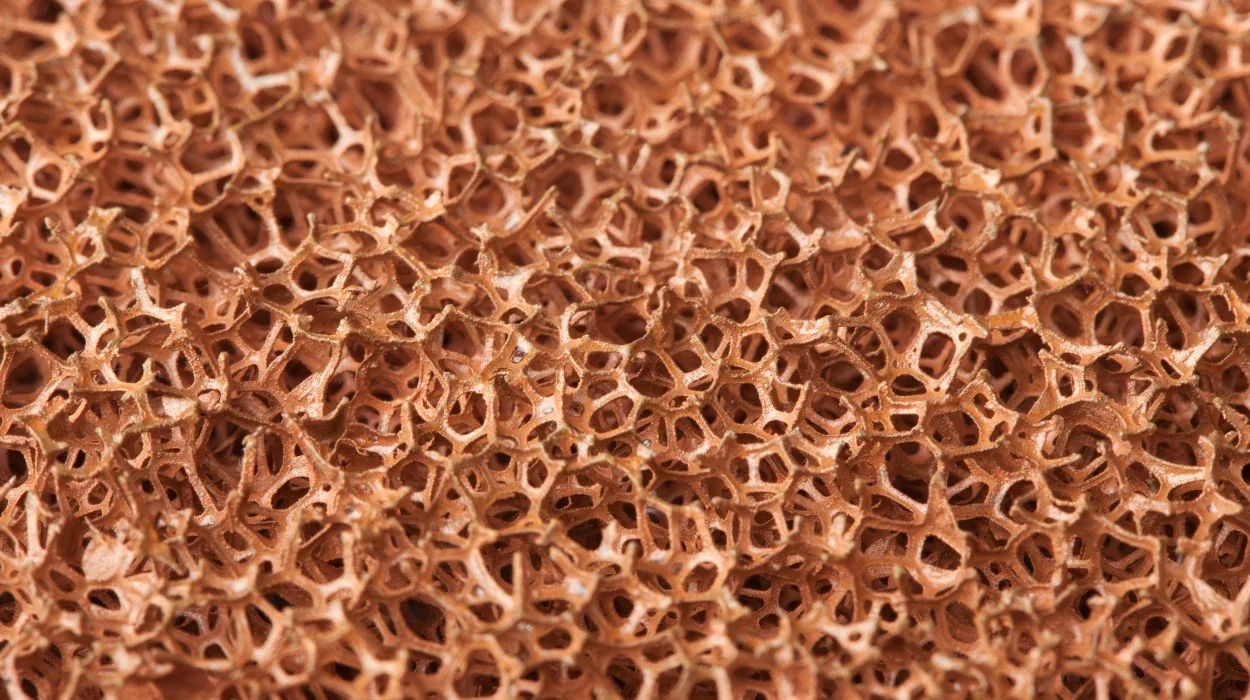

Copper metal foam is a lightweight material that looks like a sponge. It has many tiny holes or pores, which give it a unique structure. One of the most essential features of copper metal foam is its porosity—the amount of space in the material. The porosity is crucial in how the foam behaves and what it can be used for. Let’s explore why porosity is so essential when using copper metal foam.

What is Porosity?

Porosity is the presence of small openings or gaps in a material. In copper metal foam, these pores are evenly distributed throughout, giving the foam a strong and lightweight structure. Porosity is measured by the percentage of space in the material compared to the solid part.

Buy Copper Foam from leading manufacturer and supplier Techinstro and Shilpent.

Why is Porosity Important?

- Improved Heat Transfer: One of the critical benefits is its excellent ability to conduct heat. The foam metal allows the pores to heat so that the heat spreads more efficiently through the material. This is especially useful in cooling systems, heat exchangers, and electronics applications. The high porosity allows air or fluids to pass through the foam, improving heat dissipation.

- Enhanced Fluid Flow: Porous copper foam allows liquids and gases to flow easily through the material. This makes it ideal for applications such as filters or fuel cells. The open structure of the foam ensures that fluids can move through without much resistance while still capturing impurities or distributing energy.

- Lightweight Yet Strong: The porosity in copper metal foam reduces its weight while maintaining strength. This combination of lightness and strength is precious in aerospace and automotive manufacturing industries, where reducing weight can lead to better fuel efficiency without sacrificing performance.

- Increased Surface, AreaThe high porosity of copper foam provides a large surface area within a small volume. This is important in applications like batteries and catalysts, where the foam’s surface area allows more reactions. For example, the larger surface area in a battery allows for more efficient energy storage and transfer.

- Absorption of ImpactPorous copper foam can absorb shocks and vibrations due to its structure. This makes cushioning or protective equipment worthwhile, where the material can take in and reduce the impact from external forces, protecting the surrounding components.

Applications of Porous Copper Metal Foam

- Heat Sinks and Exchangers: Porous copper foam dissipates heat from electronics, keeping devices cool.

- Filters: Its open structure allows copper foam to filter gases and liquids while capturing unwanted particles.

- Energy Storage: The large surface area and lightweight nature of copper foam make it ideal for advanced batteries and fuel cells.

- Sound and Vibration Dampening: Copper foam can reduce noise and vibration in machinery and vehicles, providing a smoother and quieter operation.

Conclusion

Porosity is a critical factor in the performance of copper metal foam. It enhances the material’s ability to transfer heat, improve fluid flow, and offer lightweight strength. Whether used in energy storage, cooling systems, or filters, copper foam’s unique structure makes it a valuable material across many industries.