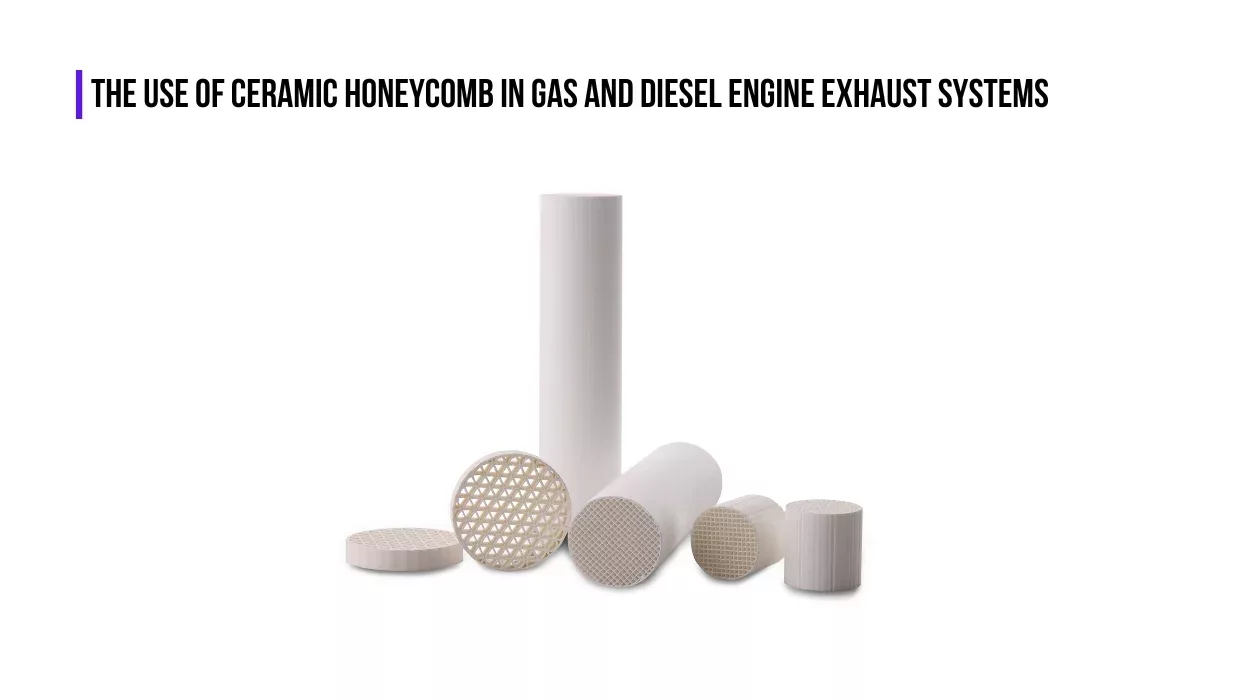

Ceramic honeycomb is a vital component in gas and diesel engine exhaust systems. Its unique structure and properties are ideal for reducing harmful emissions and improving exhaust system efficiency. Let’s explore how it works and why it is so important.

What is a Ceramic Honeycomb?

Ceramic honeycomb is a material made of ceramic, shaped into a grid-like structure with many small channels. These channels increase the surface area, making the honeycomb lightweight, strong, and efficient for various applications.

In engine exhaust systems, this material is used as a carrier for catalysts that help reduce air pollution.

How Does Ceramic Honeycomb Work in Exhaust Systems?

Traps Harmful Gases

Fuel-burning in engines releases harmful gases like carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons. The ceramic honeycomb, coated with a catalyst (like platinum, palladium, or rhodium), helps convert these gases into carbon dioxide (CO2) and water vapor which are less harmful.

Supports Catalytic Reactions

The honeycomb structure provides a large surface area for catalytic reactions to occur. As exhaust gases pass through its tiny channels, they come into contact with the catalyst, triggering chemical reactions that neutralize pollutants.

Improves Fuel Efficiency

Ceramic honeycombs also help maintain engine performance and fuel efficiency by ensuring cleaner exhaust emissions, reducing the overall environmental impact.

Why Ceramic Honeycomb?

Ceramic honeycomb has several advantages that make it suitable for use in exhaust systems:

- High Heat Resistance: It can withstand the extreme temperatures of engine exhaust gases.

- Durability: The material is solid and long-lasting, even under continuous use.

- Lightweight Design: Its lightweight structure reduces the overall weight of the exhaust system, improving vehicle efficiency.

- Eco-Friendly: By reducing harmful emissions, ceramic honeycomb is crucial in meeting strict environmental regulations.

Ceramic Honeycomb Manufacturer

Applications in Vehicles

- Gasoline Engines: Ceramic honeycomb is used in catalytic converters to control emissions in cars and motorcycles.

- Diesel Engines: In diesel engines, it is used in diesel particulate filters (DPFs) to trap and burn soot particles, reducing black smoke emissions.

- Heavy-Duty Vehicles: Trucks, buses, and other heavy vehicles rely on ceramic honeycomb to meet emission standards.

Benefits for the Environment

- Reduces air pollution by neutralizing toxic gases.

- It helps achieve global emission standards, such as Euro 6 and Bharat Stage VI norms.

- Contributes to cleaner air, benefiting public health.

Conclusion

The use of ceramic honeycomb in gas and diesel engine exhaust systems is a significant advancement in automotive technology. Its ability to trap harmful pollutants and enhance catalytic reactions makes it essential for creating cleaner, more efficient vehicles.

By integrating ceramic honeycomb into exhaust systems, manufacturers are improving vehicle performance.