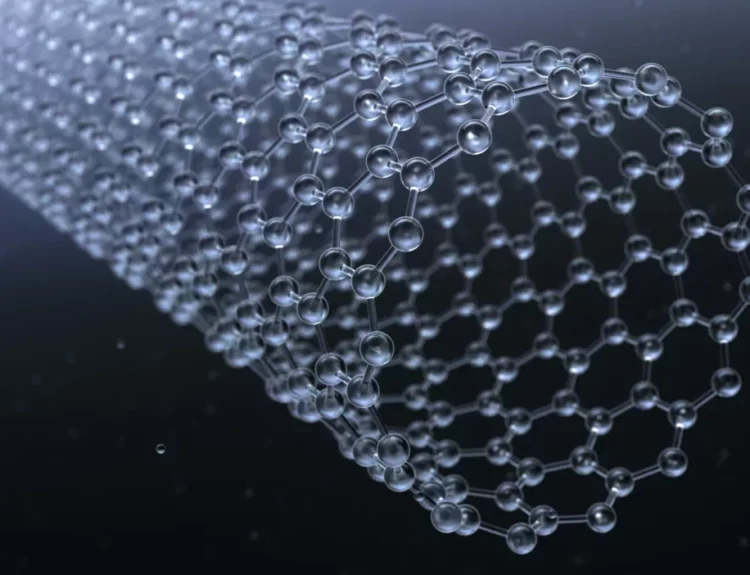

Single-walled carbon nanotubes (SWCNTs) are tiny, cylindrical structures made of just one atom thick carbon atoms. They have exceptional properties, like being incredibly strong, light, and excellent at conducting electricity and heat. Because of these qualities, scientists have been researching how to use SWCNTs in many areas, such as electronics, medicine, energy storage, and materials science. But turning a scientific discovery into a product people can use is not always simple. Let’s break down the journey of SWCNTs from the lab to industries that could use them.

The Discovery and Research Phase of Single Walled Carbon Nanotubes

The first step in the commercialization process is research. Scientists began studying carbon nanotubes in the early 1990s, and single-walled carbon nanotubes were discovered soon after. Researchers quickly realized that these tiny tubes had terrific properties, such as being many times stronger than steel yet incredibly lightweight, making them ideal for many potential applications.

However, at this stage, SWCNTs were mainly just a fascinating subject of study. Researchers had to explore how to make them in large quantities, work with them safely, and make products that could take advantage of their unique properties.

Challenges in Manufacturing Carbon Nanotubes

One of the significant hurdles in bringing SWCNTs to the market is figuring out how to make them in large quantities. In the lab, making small amounts of carbon nanotubes is relatively easy. But when it comes to large-scale production, there are challenges. The process must be cost-effective, efficient, and capable of consistently producing high-quality nanotubes.

Several methods for making SWCNTs include chemical vapor deposition (CVD), arc discharge, and laser ablation. However, each method has its challenges, like controlling the size and structure of the nanotubes or making them pure enough for practical use.

For industries to use SWCNTs, manufacturers need to develop scalable and economical processes so that the costs of producing them are low enough to be competitive with other materials already on the market.

Developing Practical Applications

Once scientists figured out how to make Single Walled Carbon Nanotubes in larger quantities, the next step was to find real-world uses for them. Researchers started exploring various industries where SWCNTs could make a difference. Some areas of interest include:

Electronics: SWCNTs can conduct electricity and heat much better than traditional materials, making them a potential game-changer in electronics. They could be used in tiny, faster transistors or as part of flexible, bendable electronics.

Energy Storage: SWCNTs can make batteries and supercapacitors lighter and more efficient. This could improve everything from smartphones to electric cars.

Materials: Adding SWCNTs to materials like plastics or metals can make them stronger and lighter. This is useful in industries like aerospace, construction, and automotive manufacturing.

However, just because SWCNTs are helpful doesn’t mean they’re ready for everyday use. It takes time to figure out how to integrate them into existing products in a way that works efficiently and safely.

Overcoming Safety and Environmental Concerns

Another concern is that, like many nanomaterials, SWCNTs could harm health or the environment if not handled properly. Before SWCNTs can be widely used, industries need to ensure they can be safely produced, transported, and disposed of without causing harm.

Researchers are still studying the environmental impact of SWCNTs, but companies are also working on improving the safety of their manufacturing processes and developing ways to reduce any adverse effects.

Commercialization and Industry Adoption

Once these challenges are addressed, the next step is getting SWCNTs into the hands of businesses that can use them to make products. Companies in industries like electronics, automotive, and healthcare are starting to adopt SWCNTs, and this has led to the development of products like:

More efficient batteries and supercapacitors.

Flexible and durable electronics, such as wearables or foldable screens.

Advanced materials used in aerospace and construction.

However, SWCNTs are still relatively expensive, so widespread use is limited. As production methods improve and costs decrease, SWCNTs will likely become more common in everyday products.

Looking to the Future

The future of SWCNTs looks promising. With ongoing research, better manufacturing techniques, and a clearer understanding of their potential risks and benefits, we can expect more and more industries to start using them. As the technology matures, we might see SWCNTs in everything from better smartphones to advanced medical treatments.

In summary, while SWCNTs started as a lab discovery, their commercialization involves overcoming technical challenges, ensuring safety, and finding the right applications. With continued progress, these amazing materials could significantly impact various industries in the coming years.