Copper foam is an innovative material attracting significant interest across a wide range of industries, from electronics to energy systems. Characterized by a highly porous structure and exceptional physical properties, copper foam stands out as a multifunctional material with strong potential for high-performance applications. In this article, we explore the structure, porosity, and conductivity of copper foam—three key factors that define its unique value.

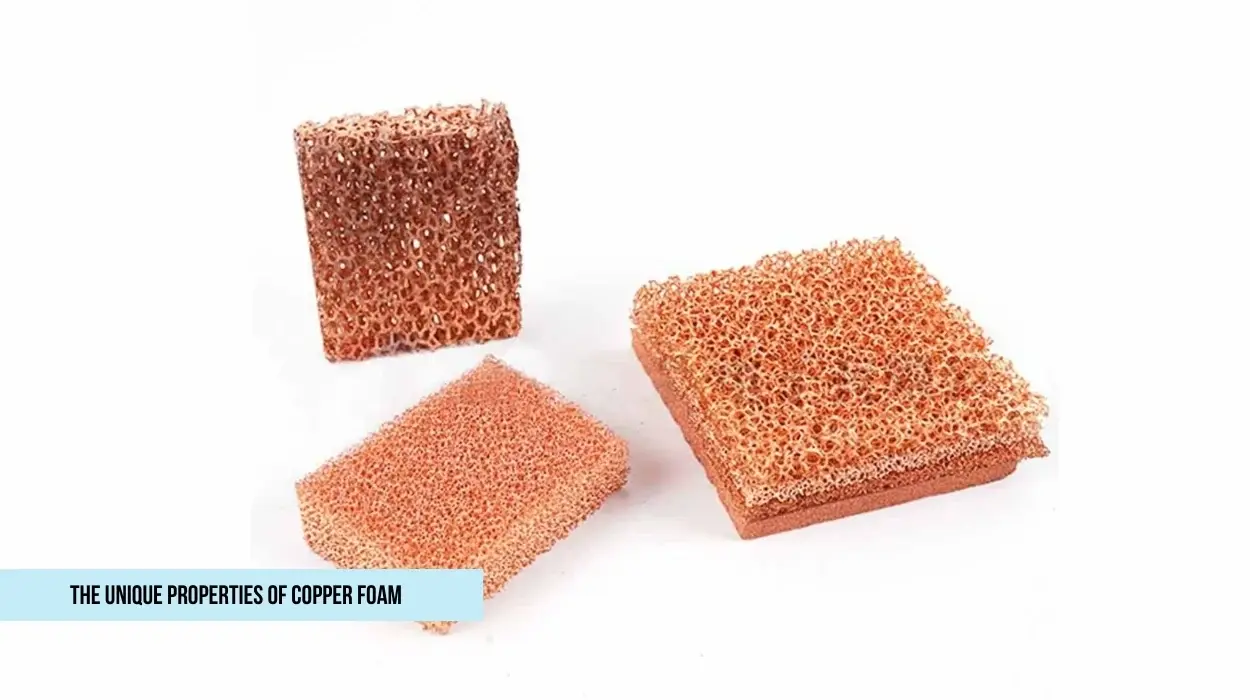

Copper Foam’s Structure: A Network of Open Cells

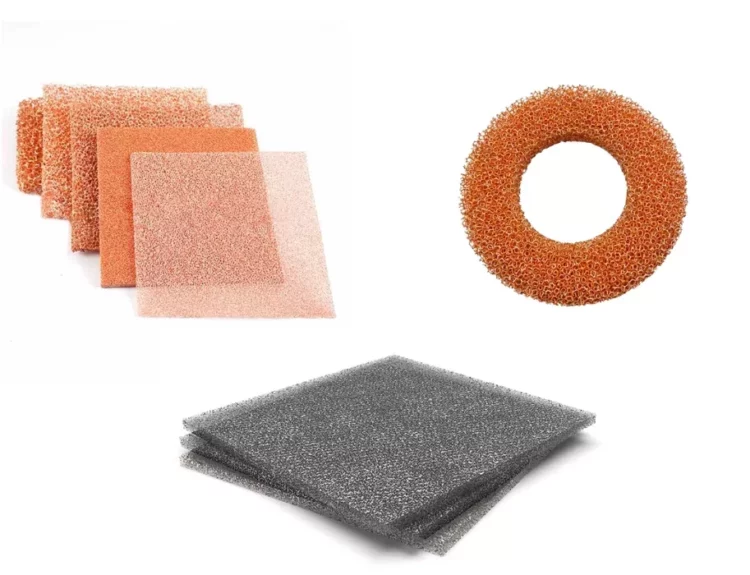

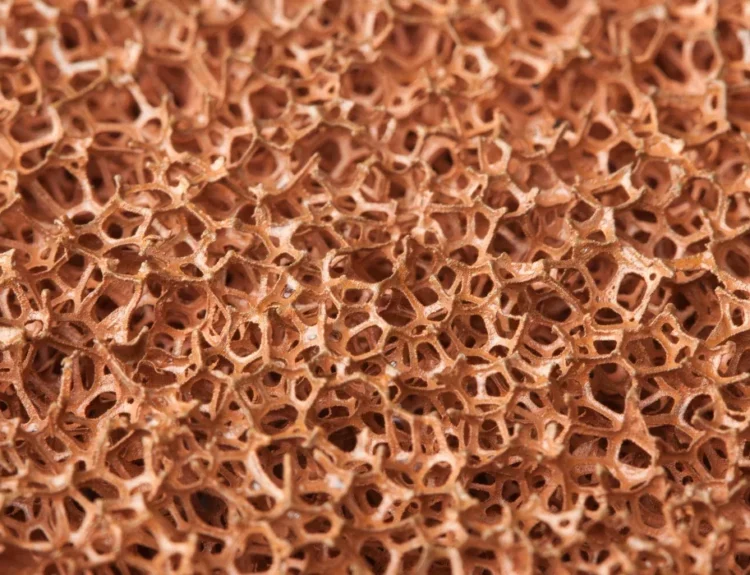

- Copper foam is typically composed of a three-dimensional network of interconnected pores. This structure can be classified as either open-cell or closed-cell, but for most applications, open-cell copper foam is preferred due to its superior fluid flow and surface area characteristics.

- Cell size and wall thickness can be precisely controlled during fabrication, typically ranging from 10 to 100 pores per inch (PPI).

- The skeleton of the foam is made of pure or alloyed copper, providing mechanical strength while minimizing weight.

- This unique geometry contributes to the foam’s lightweight nature while maintaining the mechanical integrity of solid copper.

Porosity: High Surface Area with Low Density

One of the defining features of copper foam is its high porosity, often between 80% and 98%, depending on the manufacturing method.

Why is copper foam’s porosity important?

- It significantly reduces the material’s density, making it much lighter than solid copper.

- A larger surface area enables better chemical reactions and heat exchange, which is essential for catalytic and thermal applications.

- High porosity enhances fluid permeability, making copper foam ideal for filters, flow batteries, and gas diffusion layers.

- Porosity can be tailored by adjusting fabrication parameters, allowing engineers to optimize foam performance for specific applications.

Copper Foam’s Conductivity: Keeping It Cool & Efficient

Despite being lightweight and porous, copper foam retains much of the high thermal and electrical conductivity that bulk copper is known for.

Electrical Conductivity:

- While it’s lower than pure copper due to reduced cross-sectional area, it remains high enough for use in electrodes, heat sinks, and EMI shielding.

- It provides a large conductive surface while allowing for improved gas or liquid flow in electrochemical cells.

Thermal Conductivity:

- Its ability to dissipate heat makes it invaluable in thermal management systems like cooling modules, LEDs, and battery packs.

- The open structure allows air or liquid to flow freely through the foam, enhancing convective heat transfer.

- In many cases, copper foam is used in passive cooling systems where heat needs to be spread and dissipated without mechanical assistance.

Applications Tied to These Properties

- The synergy of structure, porosity, and conductivity makes copper foam ideal for:

- Heat exchangers and heat sinks

- Battery and fuel cell electrodes

- Catalytic converters

- EMI shielding in electronics

- Fluid and gas filtration systems

Conclusion

Copper foam is more than just a lightweight metal—it’s a functional material with a unique combination of structural integrity, high surface area, and excellent thermal/electrical conductivity. As material science advances, we’re likely to see copper foam playing a crucial role in the development of next-gen energy systems, compact electronics, and sustainable technologies.