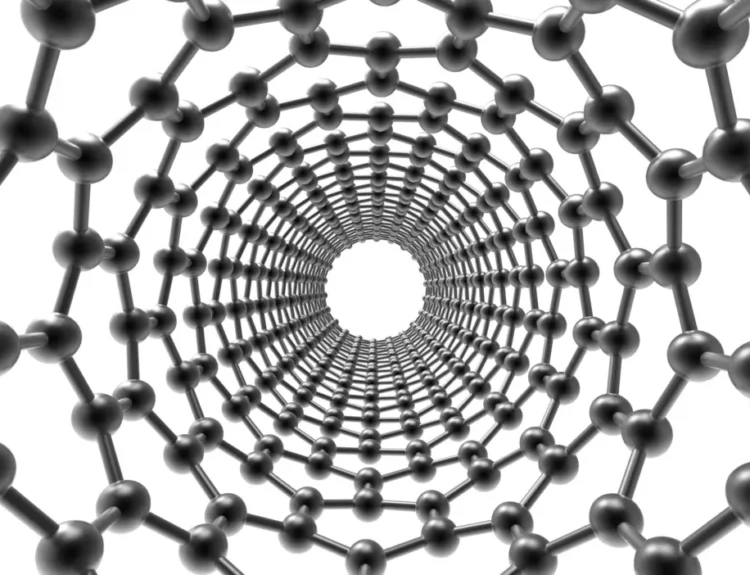

The electronics industry is undergoing a quiet revolution—one where circuits are printed like newspapers instead of etched in billion-dollar fabs. At the heart of this shift is graphene ink, a nanomaterial-based conductive ink that promises to make electronics cheaper, flexible, and more sustainable. But can it replace traditional silver inks and copper circuits? This article explores the breakthroughs, challenges, and real-world potential of graphene ink in printed electronics.

Why Graphene Ink? The Key Advantages

Superior Conductivity (With a Catch)

Pure graphene ink can achieve ~10⁶ S/m conductivity, rivaling silver ink (10⁷ S/m) at a fraction of the cost.

Problem: Most commercial “graphene inks” are graphene oxide (GO) or reduced GO (rGO), with 10³–10⁴ S/m conductivity.

Solution: New laser-reduced graphene techniques (e.g., Optomec’s Aerosol Jet) now achieve >80% of pure graphene’s performance.

Flexibility Without Fatigue

Unlike brittle metal inks, graphene ink:

Can bend >100,000 cycles without cracking (tested in foldable OLEDs).

Maintains conductivity even when stretched 20% (key for wearables).

Example: Samsung’s prototype stretchable RFID tags using graphene ink.

Cost-Effective Manufacturing

Silver ink costs ~$500/kg; high-quality graphene ink is ~$100–300/kg

Roll-to-roll printing could slash production costs by 90% vs. lithography.

Transparency for Next-Gen Displays

Graphene ink films can be >90% transparent (vs. ITO’s 85%), ideal for:

Touchscreens

Solar cell electrodes

Breakthrough: Flex Enable’s OTFTs (organic thin-film transistors) printed with graphene.

Where Graphene Ink Is Making Waves

Wearable Health Sensors

The University of Texas printed graphene-based ECG sensors directly onto skin.

Advantage: No allergic reactions (unlike silver/silver chloride electrodes).

Smart Packaging & RFID

Marks & Spencer trial: Graphene-ink RFID tags tracked **10M+ food packages** with 99.9% scan accuracy.

Benefit: 1/10th the cost of traditional tags.

Printed Batteries & Supercapacitors

Skeleton Technologies uses graphene ink for ultra-fast charging supercaps (15-second charge).

Potential: EV battery sensors printed directly on cells.

Automotive Heaters

Tesla patent: Graphene ink defroster layers for windshields (heats 5x faster than wire systems).

The Roadblocks to Mass Adoption

The “Graphene vs. Graphene Oxide” Confusion

Most “graphene inks” today are GO/rGO, not pure graphene.

Conductivity gap: rGO: 10²–10³ S/m vs. pure graphene: 10⁶ S/m.

Printing Precision Challenges

Inkjet printing struggles with clogging (graphene flakes aggregate).

Emerging fix: Electrohydrodynamic (EHD) printing (nanoscale resolution).

Stability in Real Environments

Humidity oxidation: Bare graphene ink degrades in air (solutions: hexagonal boron nitride coatings).

Regulatory Hurdles

EU’s REACH: Graphene inks face lengthy toxicity testing before commercialization.

The Future: What’s Next?

Self-Healing Inks (University of Tokyo’s microcapsule-embedded graphene).

3D-Printed Electronics (MIT’s multi-material graphene circuits).

Sustainable Production (Cambridge’s coffee waste-derived graphene ink).

Conclusion

Is Graphene Ink the Future?

Short-term: It won’t replace silicon chips, but for flexible, low-cost, and disposable electronics, graphene ink is already here.

Long-term

If conductivity and stability hurdles are cleared, it could enable ubiquitous “printed” electronics—from smart bandages to solar windows.

Key Takeaways

Cheaper than silver, more flexible than copper

Dominating wearables, RFID, and printed sensors

Still limited by graphene oxide’s lower conductivity

Future hope: Pure graphene inks + self-healing tech