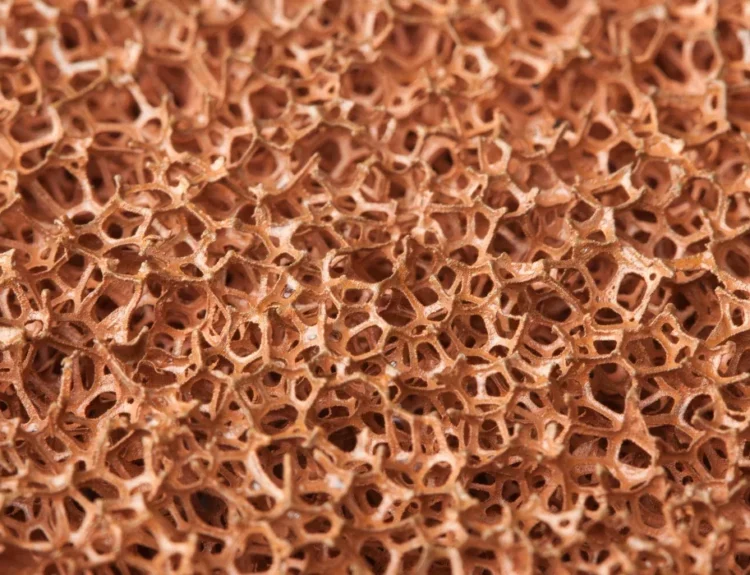

Imagine a sponge, but instead of being soft and full of water, it’s made of metal, conducts electricity perfectly, and is tough enough to be used in cutting-edge batteries and clean energy devices. That’s nickel foam.

But how do you actually make a metal sponge? You can’t just pour it into a mold. The creation of nickel foam is a fascinating process of engineering emptiness, and scientists are constantly refining it to build a better, more efficient material.

The Classic Recipe: Electroplating a Plastic Sponge

The most common method for making nickel foam is known as the template method. Think of it like making a chocolate sculpture by coating a plastic shape and then melting the plastic away.

Find a Template (The “Sacrificial Skeleton”): You start with a piece of polyurethane foam the same soft, flexible foam used in couch cushions or mattress toppers. This foam has a perfect, interconnected network of pores and struts. This is your template.

Conductivity Coat: Plastic doesn’t conduct electricity, so you can’t electroplate it directly. First, the foam is put through a special process called electroless plating. It’s dipped in a chemical solution that adheres a thin layer of nickel or other metal to every single plastic strand, making the entire foam template conductive.

Electroplating (Building the Metal): Now, the conductive foam is submerged in a bath of nickel salts (an electrolyte) and hooked up to an electrical current. This process, called electrodeposition, slowly pulls nickel atoms out of the solution and deposits them onto the conductive template, building up a solid metal skin over the entire plastic structure.

The Heat Treatment (The Final Transformation): The now metal-coated foam is placed in a very hot oven. This step does two critical things:

It vaporizes and burns away the original plastic polyurethane template, leaving behind a hollow, metallic replica.

It anneals the nickel, making the metal stronger and less brittle.

The final product is an incredibly lightweight, porous, and rigid piece of pure nickel foam.

How Do You Make it “Better”?

The “better” in manufacturing depends entirely on what the foam will be used for. Scientists play with the recipe to get exactly the right properties:

The Cutting Edge: New Ways to Build

The template method is excellent, but it has limits (like the leftover impurities from burning the plastic). So, researchers are exploring new, futuristic ways to make nickel foam:

Freeze Casting: Imagine freezing metal soup! A slurry of nickel particles in water is slowly frozen. As ice crystals form, they push the nickel particles into the spaces between them, creating aligned, porous channels. The ice is then freeze-dried away, leaving a solid porous structure.

3D Printing (Additive Manufacturing): This is the ultimate control. Scientists can now 3D print intricate designs of nickel powder, layer by layer, to create foams with perfectly tailored pore shapes, sizes, and distributions that are impossible to achieve with traditional templates.

The Bottom Line

Making nickel foam isn’t just about creating metal; it’s about sculpting emptiness. By carefully choosing the template and controlling the plating process, engineers can design this versatile material from the ground up, tailoring it to power the next generation of technology. It’s a perfect example of how mastering a manufacturing process can unlock a material’s true potential.