When you think of soundproofing, you probably imagine soft egg-carton foam, heavy velvet curtains, or thick fiberglass insulation. These materials work well for a home studio or a bedroom, but what happens when you need to silence a jet engine, a high-pressure steam pipe, or a chemical processing plant?

Soft foams melt. Curtains catch fire. Fiberglass degrades.

Enter the newest trend in industrial design: Metal Soundproofing Panels, specifically those powered by Nickel Foam. These metallic structures are changing how we manage noise in the world’s harshest environments.

Why Metal? The Problem with Traditional Materials

In industrial settings, noise isn’t just an annoyance; it’s a safety hazard. However, the environments that produce the most noise are often high-heat, high-moisture, or high-vibration.

Fire Safety: Most acoustic foams are petroleum-based. In a fire, they can release toxic smoke or act as an accelerant.

Durability: In aerospace or marine engineering, materials are pelted by wind, salt, and debris. Soft materials simply shred over time.

Hygiene: In food processing or clean room manufacturing, porous foams trap bacteria and dust. Metal can be sterilized.

The Science: How a Nickel Foam Stops Sound

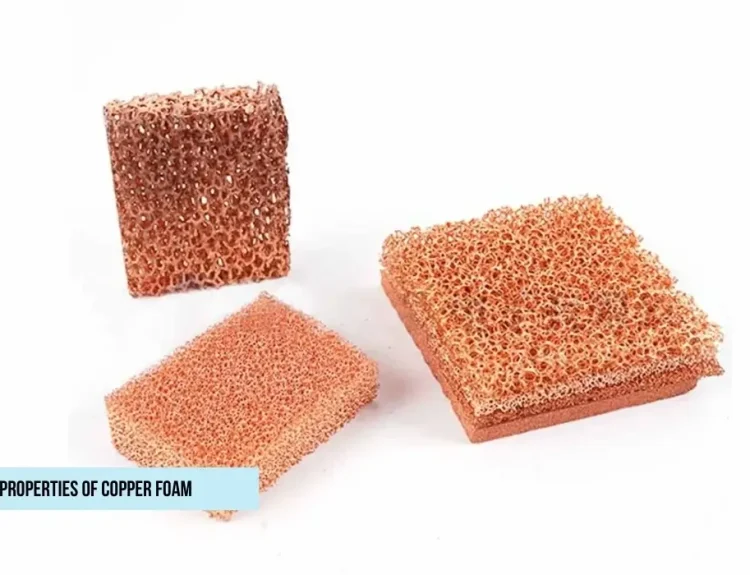

It seems counterintuitive. Metals are usually resonant, think of a ringing bell. But when Nickel or aluminum is processed into a “foam” (an open-cell cellular structure), it becomes an acoustic powerhouse.

When sound waves hit a Nickel foam panel, they don’t just bounce off. Instead, they enter a labyrinth of microscopic, interconnected pores. As the air molecules vibrate through these tiny metallic tunnels, their energy is converted into a tiny amount of heat through friction.

The result? The sound is absorbed by the metal rather than reflected.

Where You’ll See Them in 2026

The adoption of these panels is skyrocketing across three major sectors:

Aerospace & Aviation: Engineers are lining jet engine nacelles with Nickel foam panels. They can withstand the scorching exhaust temperatures while significantly reducing the “roar” heard by passengers and neighborhoods near airports.

Data Centers: High-performance servers require massive cooling fans that create a constant, high-frequency whine. Metal panels provide a fireproof way to dampen this noise without restricting the airflow needed to keep the chips cool.

Luxury Architecture: Architects are using laser-etched metal acoustic panels in modern lobbies and transit hubs. They provide a sleek, “industrial-chic” look while solving the echo problems common in large glass-and-steel buildings.

Conclusion: A Quiet, Rugged Future

The rise of metal soundproofing panels represents a shift toward permanent, sustainable engineering. While foam needs to be replaced every few years as it crumbles or clogs, a Nickel foam panel can last as long as the building or machine it is attached to.

As our cities get denser and our machinery gets more powerful, the need for rugged silence will only grow. Metal panels have proven that you don’t need soft materials to get soft results. Sometimes, the best way to quiet the world is with the toughest material available.