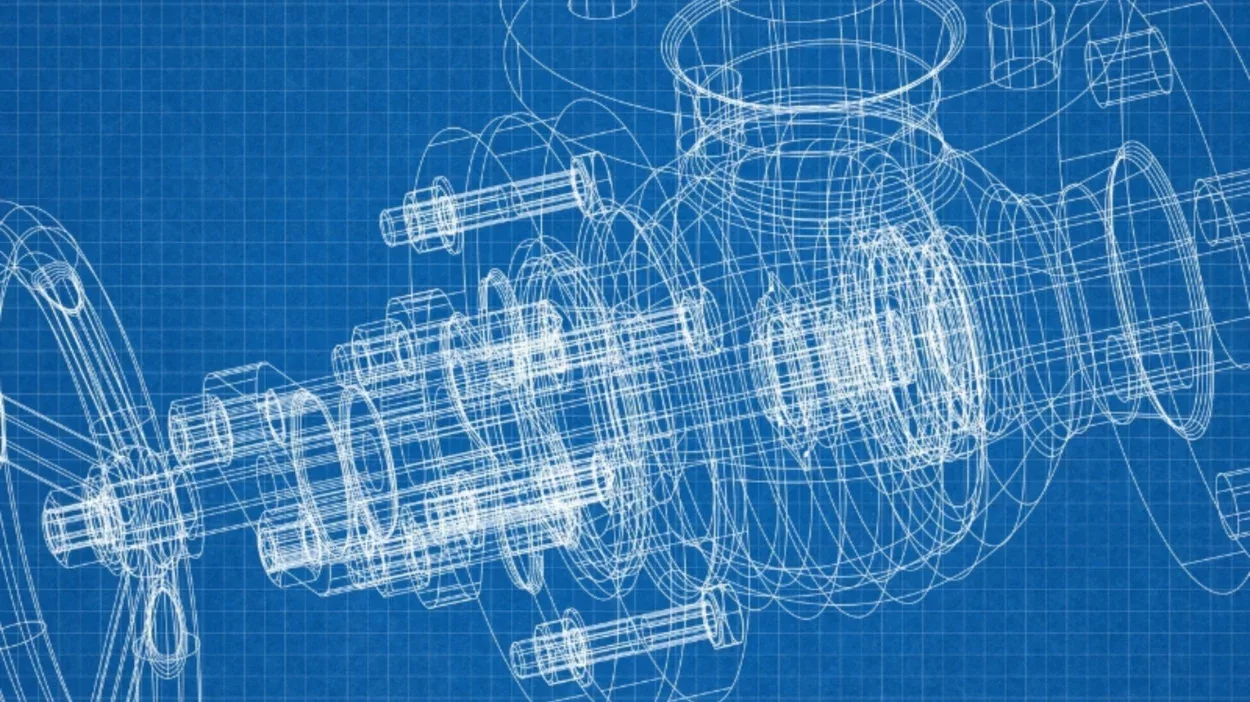

Introduction: When it comes to industrial operations, safety is paramount. In emergencies, quick and effective responses can make all the difference. That’s where emergency shutdown systems (ESDs) come in. In this article, we’ll explore the crucial role of pressure safety valves (PSVs) in ESDs and how they work together to keep people and equipment safe during crises.

Understanding Emergency Shutdown Systems (ESDs)

Imagine you’re driving a car and suddenly need to stop immediately to avoid an accident. ESDs work similarly in industrial settings but on a much larger scale. They’re designed to shut down operations swiftly and safely in response to hazardous situations like leaks, fires, or equipment malfunctions. This rapid response helps prevent accidents, protect workers, and reduce environmental property damage.

The Importance of Pressure Safety Valves (PSVs)

Pressure safety valves are not just components, they are precision instruments. They constantly monitor and regulate pressure levels, ensuring that they never exceed safe limits. When pressure does reach a critical point, PSVs spring into action, opening and releasing fluid or gas with precision. This crucial function helps prevent over-pressurization, which can lead to equipment failures, explosions, or other catastrophic incidents.

Integrating PSVs into ESDs

In emergencies, every second counts. That’s why PSVs are integral components of ESDs. When an ESD is activated, it sends a signal to PSVs to initiate a rapid pressure release, returning pressure levels to safe operating ranges. This controlled shutdown helps stabilize the system, prevent further escalation of the crisis, and provide valuable time for response teams to assess the situation and take appropriate actions.

Ensuring Effectiveness and Reliability

Regular maintenance and testing are essential to ensure ESDs with integrated PSVs function effectively. But it’s not just about the equipment. Proper training for personnel on ESD procedures and PSV operation is a key factor in enhancing readiness and response capabilities. Routine inspections, calibration checks, and performance tests help determine potential problems and ensure the system operates as intended during emergencies.

Real-World Applications

ESDs with integrated PSVs are not just theoretical concepts; they are real-life heroes. They are widely used across various industries, including chemical processing, power generation, and manufacturing. Whether shutting down a refinery to prevent a major spill or stopping a chemical reaction to avoid an explosion, these systems play a critical role in safeguarding personnel, facilities, and the environment. Your work with these systems is making a tangible difference in the world.

Conclusion

In a crisis, robust emergency shutdown systems with integrated pressure safety valves can differentiate between a manageable incident and a catastrophic disaster. By working together seamlessly, these technologies help protect lives, minimize damage, and ensure industrial processes’ safe and reliable operation. So, the next time you see a PSV in action during an emergency shutdown, remember its vital role in keeping everyone safe.

To purchase this product, please follow the link below.

1- Techinstro