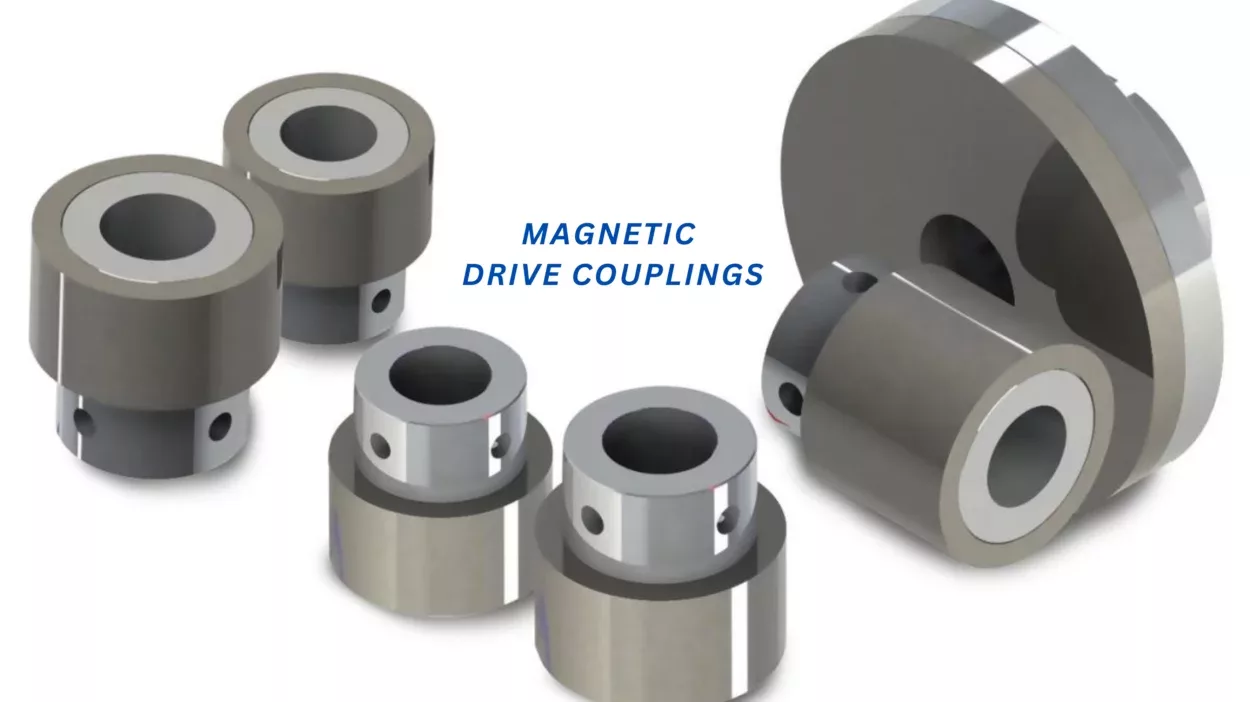

Magnetic drive couplings, a true marvel of engineering, may sound like a concept from a sci-fi movie, but they’re more than just cool devices. These ingenious couplings, with their unique ability to connect different machine parts without any physical contact, truly captivate the imagination, especially when maintaining a tight seal is crucial.

So, how do they work? Well, it’s all about magnets! Instead of using gears or shafts like traditional couplings, magnetic drive couplings use potent magnets to transfer torque from one part of a machine to another. It’s like magic but with magnets instead of wands!

The basic idea is simple. You want to connect two parts of a machine, like an input shaft and an output shaft. Each part has a set of magnets arranged in a specific way to attract each other. When you put the two parts close together, the magnets pull on each other, creating a solid connection that allows torque to be transferred from one part to the other.

But here’s the truly remarkable aspect – the connection is entirely magnetic, eliminating the need for physical contact between the two parts. This unique safety feature allows for a complete seal, a vital advantage in scenarios involving hazardous or corrosive fluids. It’s akin to having a protective force field around your machine, ensuring everything remains safe and secure.

One of the most impressive aspects of magnetic drive couplings is their exceptional efficiency. With no friction between the two parts, there’s no energy wasted as heat. This translates to the ability to transfer torque from one part to the other with minimal loss, a significant boon for energy conservation and the smooth operation of your machines.

Of course, designing magnetic drive couplings is more challenging than just sticking some magnets together and calling it a day. Engineers have to carefully design the layout of the magnets to ensure they create enough force to transfer the torque but not so much that they’re impossible to separate when needed.

They also have to consider things like alignment—if the magnets aren’t perfectly lined up, the coupling won’t work correctly. That’s why you’ll often see magnetic drive couplings with unique features like bearings or alignment pins to ensure everything stays in place.

But when it all comes together, magnetic drive couplings can be incredibly useful devices. They’re used in all sorts of machines, from pumps and mixers to fans and compressors, and they help keep things running smoothly and safely in all kinds of industries.

So, the next time you see a machine that needs to transfer torque without any physical contact, remember the magic of magnetic drive couplings – they might be the secret behind its smooth operation!