Introduction

Graphene conductive ink is a revolutionary material that combines graphene’s extraordinary properties with ink’s versatility. This ink can be used in various applications, such as flexible electronics, printed circuits, and wearable devices. Understanding how this ink is made is critical to appreciating its potential. This article will explain the techniques used to fabricate graphene conductive ink in simple terms.

What is Graphene Conductive Ink?

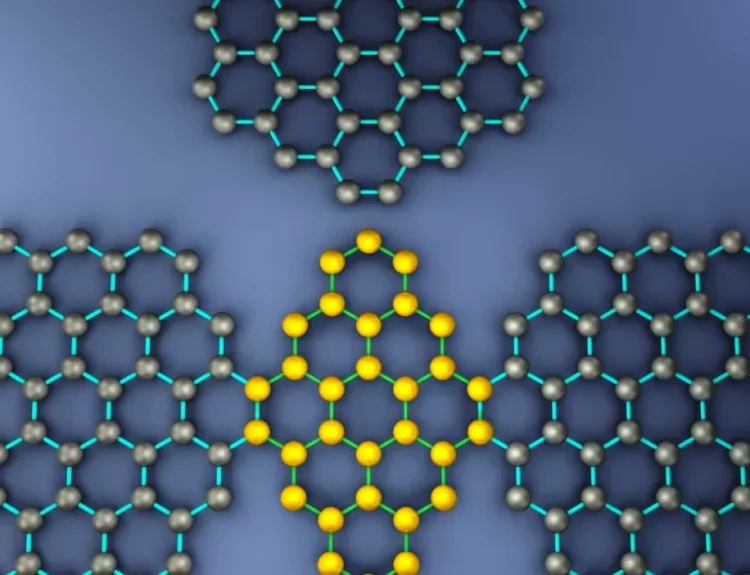

Graphene is one layer of carbon atoms arranged in a hexagonal lattice. It’s solid, lightweight, and an excellent conductor of electricity. Graphene retains these properties when mixed into ink, making it ideal for printing electronic circuits and other conductive patterns on various surfaces.

Exfoliation Methods

Liquid-Phase Exfoliation

- Process: Ultrasonic waves separate Graphene sheets from graphite in a liquid medium.

- How It Works: Graphite (the stuff in pencil lead) is placed in a liquid and then blasted with sound waves. This process breaks the graphite into single layers of graphene.

- Benefits: This method is relatively simple and can produce large amounts of graphene.

- Challenges: It can take a lot of work to get very high-quality graphene sheets.

Mechanical Exfoliation

- Process: This involves physically peeling off layers of graphene from graphite.

- How It Works: Using a sticky tape-like method, layers are repeatedly peeled away from graphite until only a single graphene layer remains.

- Benefits: Produces high-quality graphene.

- Challenges: It could be more practical for large-scale production.

Chemical Vapor Deposition (CVD)

- Process: Graphene is grown on a substrate by decomposing a carbon-containing gas.

- How It Works: A metal surface (usually copper) is heated in a furnace with gases like methane. The carbon atoms from the gas settle on the metal surface, forming a graphene layer.

- Benefits: Produces high-quality and large-area graphene sheets.

- Challenges: It’s complex and expensive, making it less ideal for mass production.

Reduction of Graphene Oxide (GO)

- Process: Graphene oxide (a non-conductive form of graphene) is chemically or thermally reduced to make it conductive.

- How It Works: Graphite is oxidized to create graphene oxide, then dispersed in water or another solvent. This dispersion is reduced (chemically or with heat) to convert it back into conductive graphene.

- Benefits: This method is relatively easy and scalable.

- Challenges: The quality and conductivity of the resulting graphene can vary.

Solvent Exfoliation

- Process: Graphene is exfoliated in a suitable solvent.

- How It Works: Similar to liquid-phase exfoliation, it specifically focuses on finding the suitable solvent to separate graphene layers efficiently.

- Benefits: It can produce high-quality graphene that is ideal for various applications.

- Challenges: Finding the perfect solvent can be tricky, and the process can be time-consuming.

Combining Graphene with Ink

Once graphene is produced using one of the methods above, it must be mixed with a liquid to create ink. This involves:

- Dispersing Graphene: The graphene particles are dispersed in a solvent to create a uniform mixture. Surfactants or stabilizers might be added to keep the particles evenly distributed.

- Formulating the Ink: The dispersed graphene is mixed with other components, like binders and additives, to create the final ink that can be printed or coated onto surfaces.

Applications of Graphene Conductive Ink

- Flexible Electronics: Used in creating bendable screens and circuits.

- Printed Circuits: Ideal for low-cost, large-scale production of electronic components.

- Wearable Devices: Enables the creation of smart textiles and other wearable tech.

Conclusion

The fabrication of graphene conductive ink involves several sophisticated techniques, each with advantages and challenges. From exfoliating graphene layers to reducing graphene oxide and creating uniform dispersions, these methods make graphene conductive ink a versatile and robust material for modern electronics. As technology grows, we can expect more efficient and scalable ways to produce high-quality graphene ink, opening up new possibilities in the world of flexible and printed electronics.

To purchase this product, please follow the links below.

1- Techinstro

2- Shilpent