Project Goal: Build a Better Epoxy

The challenge was clear: create an epoxy composite that conducts electricity while remaining stronger than standard epoxy. This combination of properties doesn’t exist in nature—regular epoxy is strong but completely insulating. By adding graphene, we aimed to develop a material that could protect electronic components from static electricity while also withstanding greater weight and stress. This case study walks through exactly how we did it.

Why Graphene? Why Epoxy?

Epoxy was chosen because it’s widely used in industries from aerospace to electronics. It bonds well, resists chemicals, and is relatively easy to work with. However, it breaks under stress and doesn’t conduct electricity.

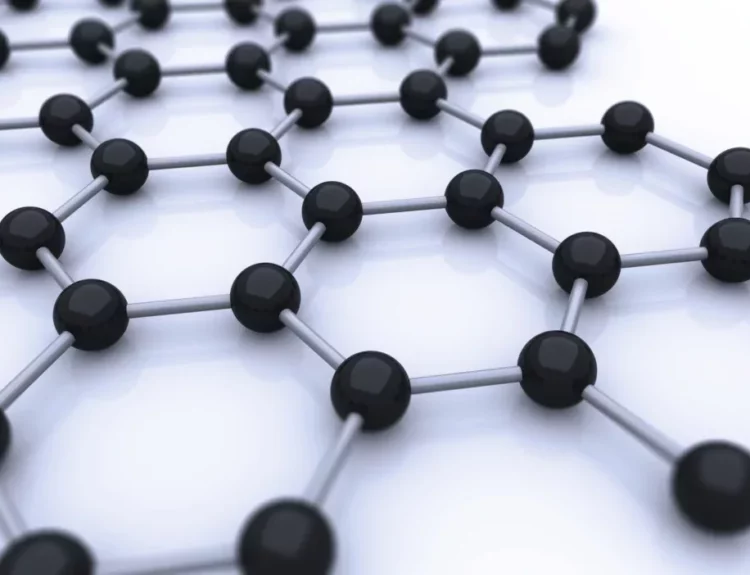

Graphene—in the form of few-layer nanoplatelets—was selected because it offers:

- Exceptional strength (200 times stronger than steel)

- High electrical conductivity

- Good thermal properties

- A high surface area to interact with the epoxy

- The trick was getting these two materials to work together correctly.

- The Two-Step Mixing Method That Worked

- Getting graphene to mix evenly into epoxy is surprisingly tricky. Graphene sheets naturally clump together like wet paper. We developed a two-step process to solve this.

Step 1: Preparing the Graphene

- We begin with graphene nanoplatelets, which are thin stacks of graphene sheets.

- To prevent clumping, we added a dispersant called PVP.

- We then mixed the graphene with acetone using ultrasonic sound waves for 30 minutes.

- Afterward, we evaporated the acetone, leaving us with coated graphene that is ready to be mixed.

Step 2: Mixing with Epoxy

- First, blend the prepared graphene with a small amount of epoxy (creating a “masterbatch”)

- Then, I mixed this concentrated blend with the rest of the epoxy

- Removed air bubbles using a vacuum

- Added the hardening agent and poured it into molds

- Cured at room temperature, then finished at 80°C

- What We Measured: The Results

Electrical Conductivity:

- Pure epoxy: Complete insulator (less than 0.000000000001 S/m)

- 1% graphene epoxy: Conducted electricity at 0.01 S/m

- This is a 10-billion-times improvement—enough to dissipate static electricity safely

Mechanical Strength:

- Tensile strength: Increased by 22% (from 65 MPa to 79 MPa)

- Stiffness: Increased by 35% (from 2.8 GPa to 3.8 GPa)

- The graphene acted like microscopic reinforcement bars in concrete

Other Properties:

- Heat resistance: Unchanged—still stable to about 120°C

- Thermal conductivity: Improved by about 15%

- Weight: Only increased by 1% (the graphene loading)

The Challenges We Faced

- Thickness: Adding graphene made the epoxy thicker and harder to pour

- Bubbles: More mixing meant more trapped air to remove

- Consistency: Ensuring every batch is mixed the same way

- Scaling: What works in the lab (grams) needs adjustment for factory production (kilograms)

Key Lessons Learned

What Worked Well:

- The two-step mixing process effectively minimizes clumping

- A 1% graphene concentration proved to be the optimal balance between conductivity and workability.

- Non-ionic dispersants, such as PVP, were more effective than ionic dispersants.

What We’d Do Differently Next Time:

- Test functionalized graphene that chemically bonds with epoxy.

- Experiment with different mixing equipment for larger batches.

- Try lower graphene percentages (e.g., 0.5%) for applications that require lower conductivity.

Real-World Applications

This graphene-epoxy composite could be used for:

- Circuit board coatings that protect against static discharge

- Aircraft and auto parts that need to be strong and electrically safe

- Sports equipment like lighter, stiffer bicycle frames or tennis rackets

- Industrial tooling that doesn’t build up static electricity

Conclusion

This project proved that graphene can transform ordinary epoxy into a multifunctional material. We successfully created a composite that conducts electricity while being significantly stronger—achieving both goals in one material. The key was proper dispersion: treating the graphene first, then carefully mixing it into the epoxy.

The results show that 1% graphene loading reaches what engineers call the “percolation threshold”—the point at which enough graphene particles connect to form conductive pathways while also reinforcing the epoxy structure. This isn’t just mixing; it’s creating a new material architecture at the nanoscale.

For industries looking to make lighter, stronger, more innovative materials, this case study provides a practical blueprint. The process is repeatable, the materials are commercially available, and the property improvements are substantial. As the cost of producing graphene continues to decrease, these advanced composites are expected to shift from specialized applications to everyday uses, improving the durability and functionality of items ranging from electronics to vehicles.