Graphene nanoplatelets (GNPs) are thin stacks of graphene layers that come in tiny, plate-like shapes. They are a special form of graphene and have some unique properties that make them useful in many industries, including electronics, energy, and materials science. In this article, we’ll explore what graphene nanoplatelets are, their features, and why they’re important.

What Are Graphene Nanoplatelets?

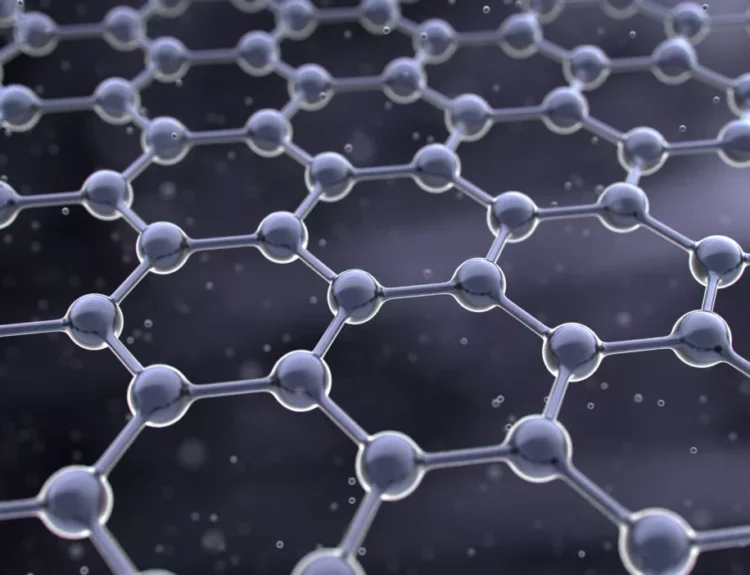

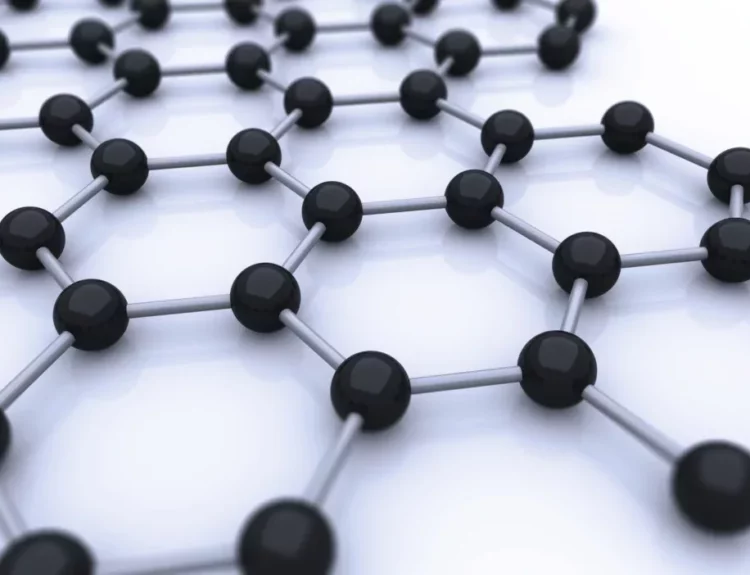

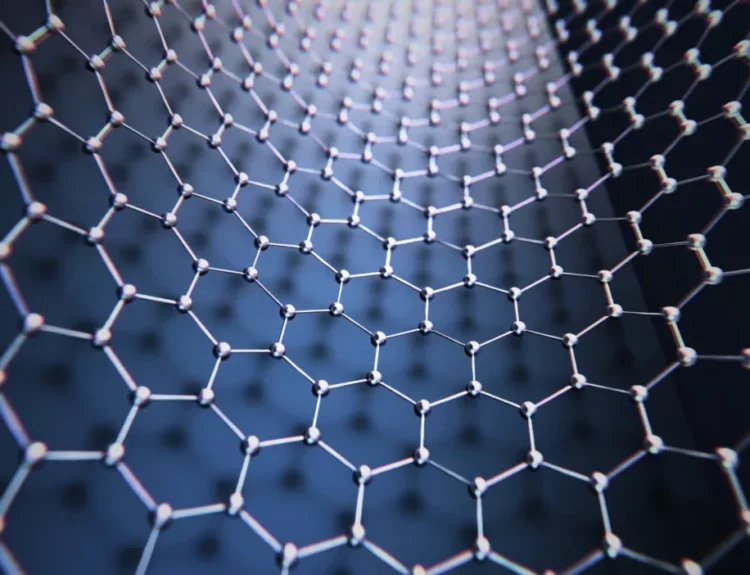

Graphene nanoplatelets are made from small layers of graphene that are stacked on top of each other. Graphene itself is a single layer of carbon atoms arranged in a hexagonal pattern. When multiple layers of graphene are combined, they form nanoplatelets, which are thin but have a relatively large surface area.

The thickness of graphene nanoplatelets can vary, but they are typically only a few nanometers thick (a nanometer is one-billionth of a meter). Despite being so thin, they are incredibly strong, lightweight, and have excellent electrical and thermal conductivity.

Graphene Nanoplatelets Sellers

Key Features of Graphene Nanoplatelets

- High Strength – Graphene nanoplatelets are extremely strong, even though they are thin. They are about 200 times stronger than steel by weight, making them valuable for reinforcing materials like plastics or metals.

- Lightweight – Despite their strength, GNPs are incredibly light, which makes them useful in industries that need strong but lightweight materials, such as aerospace and automotive.

- Excellent Conductivity – GNPs can conduct electricity and heat very well. This makes them useful in applications like batteries, supercapacitors, and electronics, where efficient energy transfer is important.

- Large Surface Area – Because of their thin, plate-like structure, graphene nanoplatelets have a large surface area. This is important in applications like sensors and energy storage, where the material needs to interact with other substances.

Applications of Graphene Nanoplatelets

- Composite Materials – Graphene nanoplatelets can be mixed into materials like plastics, metals, and rubber to make them stronger, lighter, and more durable. For example, adding GNPs to plastic can make it tougher without adding much weight, which is useful in industries like construction and sports equipment manufacturing.

- Energy Storage – GNPs are used in batteries and supercapacitors because they can store and transfer energy efficiently. Their high conductivity helps improve the performance of these energy storage devices, making them last longer and charge faster.

- Thermal Management – Since GNPs can conduct heat very well, they are used in applications where heat needs to be quickly dissipated, such as in electronics or heat sinks. This helps prevent devices from overheating and improves their performance.

- Coatings and Inks – Graphene nanoplatelets are used in conductive inks and coatings. These materials can be applied to surfaces to make them electrically conductive, which is useful in printed electronics or flexible circuits.

- Barrier Materials – GNPs can also act as a barrier to gases and liquids, making them useful in packaging, especially for food or sensitive electronics. They prevent moisture and oxygen from penetrating the material, helping to preserve the contents.

Why Are Graphene Nanoplatelets Important?

Graphene nanoplatelets are important because they combine strength, lightness, and conductivity in one material. This makes them valuable in a wide range of industries. Their ability to improve the properties of other materials, like increasing the strength of plastics or making batteries more efficient, shows their potential for transforming many products and technologies.

In addition, GNPs are cost-effective compared to single-layer graphene, making them more accessible for large-scale applications.

Conclusion

Graphene nanoplatelets are a remarkable material with a wide range of uses due to their strength, light weight, and excellent conductivity. From improving the performance of batteries to making materials stronger, GNPs are becoming increasingly important in various industries. Their unique properties make them a key material for future innovations in energy, electronics, and advanced materials.