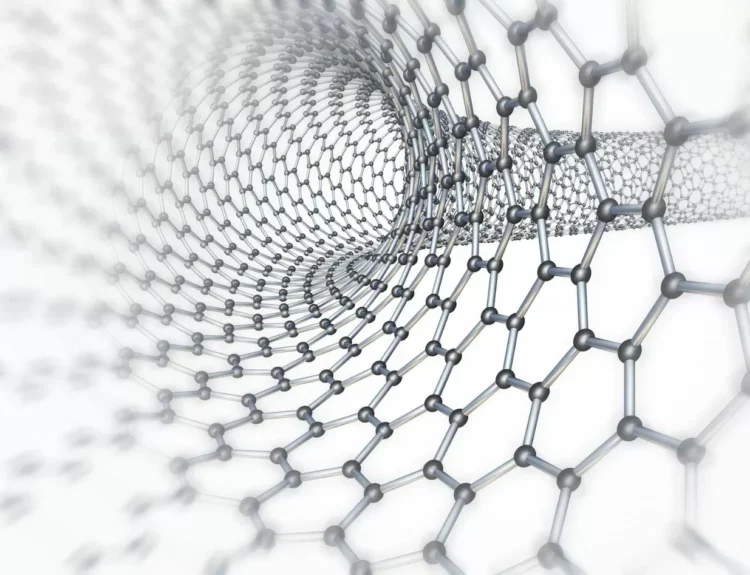

Graphene Oxide (GO) is a fascinating nanomaterial that has garnered attention recently due to its unique properties and diverse applications. However, the production of graphene oxide is a complex process, and it’s essential to understand its advantages and disadvantages. In this article, we will explore how graphene oxide is produced and discuss the pros and cons of this remarkable material.

Production of Graphene Oxide:

Graphene oxide is primarily produced through the chemical oxidation of graphite. The process involves several steps, with the main ones being:

- Graphite Exfoliation:Natural graphite is intercalated with strong acids, leading to the expansion of its crystal structure. This results in the formation of graphite intercalation compounds (GICs).

- Oxidation:The GICs are further oxidized, typically using a mixture of strong acids, such as sulfuric acid and potassium permanganate. The process introduces oxygen-containing functional groups to the graphene layers, creating graphene oxide.

- Exfoliation and Separation:The oxidized material is then exfoliated and dispersed in a solvent, producing a stable suspension of graphene oxide sheets.

- Reduction (Optional):To obtain reduced graphene oxide (rGO), the graphene oxide can be chemically or thermally reduced, which restores some of its electrical conductivity and removes some oxygen groups.

Advantages of Graphene Oxide:

- Versatility:Graphene oxide is incredibly versatile and can be tailored for various applications through functionalization, making it suitable for various industries.

- Water Dispersion:Unlike pristine graphene, graphene oxide readily disperses in water, making it easy to work with and suitable for various liquid-phase applications, such as inks, coatings, and composites.

- Biocompatibility:Graphene oxide exhibits biocompatible properties, allowing its use in biomedical applications like drug delivery, tissue engineering, and biosensing.

- Exceptional Mechanical Strength:While not as strong as pristine graphene, graphene oxide still boasts impressive mechanical properties, reinforcing composite materials and enhancing their strength and durability.

- High Surface Area:The oxygen-containing functional groups on the graphene oxide surface result in a high surface area, making it an excellent material for adsorption, catalysis, and energy storage applications.

Disadvantages of Graphene Oxide:

- Reduced Electrical Conductivity:The introduction of oxygen-containing functional groups during the oxidation process significantly reduces the electrical conductivity of graphene oxide compared to pristine graphene.

- Complex Production Process:The production of graphene oxide involves multiple steps and strong acids, making it a complex and potentially hazardous process.

- Limited Structural Integrity:Graphene oxide sheets are often less mechanically robust than pristine graphene, it can limit its use in applications that require extreme mechanical strength.

- Variable Quality:The quality and properties of graphene oxide can vary depending on the production methods and conditions, making it essential to control the synthesis process carefully.

- Environmental Concerns:Using strong acids in the production process can raise environmental and safety concerns. Developing greener and more sustainable production methods is an ongoing challenge.

In conclusion, graphene oxide is a fascinating material with numerous advantages, but it has drawbacks. Its production process is intricate, and the resulting material’s properties vary. Researchers and engineers are continually exploring ways to harness the benefits of graphene oxide while mitigating its disadvantages. As technology and understanding of this remarkable nanomaterial evolve, we expect to see an increasing number of innovative applications across various industries.