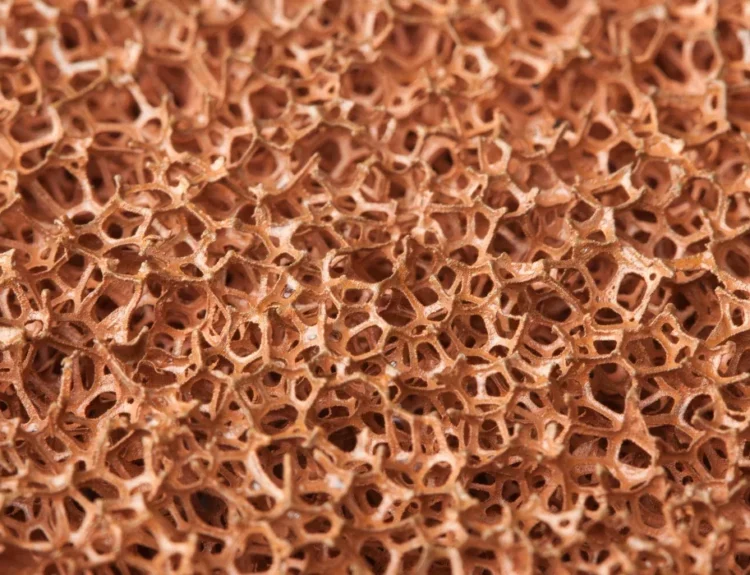

Aluminum foam is a lightweight, porous material with unique properties like high strength, energy absorption, and thermal insulation. It’s used in the automotive, aerospace, and construction industries. But how is it made? Let’s explore the various production methods in a straightforward and easy-to-understand manner.

Aluminum Foam Casting Methods

Melt Route

This is one of the most common methods for producing aluminum foam.

Process:

Melting Aluminum: Pure aluminum or an alloy is melted in a furnace.

Adding Foaming Agent: A foaming agent (like titanium hydride or calcium carbonate) is mixed into the molten aluminum.

Decomposition & Gas Release: When heated, the foaming agent decomposes, releasing gas bubbles (usually hydrogen).

Controlled Cooling: The molten Foam is cooled slowly to stabilize the bubbles, creating a solid foam structure.

Advantages:

Low cost

Suitable for large-scale production

Good control over pore size

Disadvantages:

Requires precise temperature control

Pores may not be perfectly uniform

Powder Metallurgy (Sintering Method)

This method is ideal for making small, high-quality aluminum foam parts.

Process:

Mixing Powders: Aluminum powder is mixed with a foaming agent (like titanium hydride).

Compression: The mixture is compressed into a solid compact.

Heating (Sintering): The compact is heated just below aluminum’s melting point, causing the foaming agent to release gas and create pores.

Cooling: The material solidifies into Foam.

Advantages:

Uniform pore structure

Good mechanical properties

Can make complex shapes

Disadvantages:

Expensive

Limited to smaller parts

Aluminum Foam Gas Injection Method

Instead of a foaming agent, gas is directly injected into molten aluminum.

Process:

Melting Aluminum: Aluminum is melted in a furnace.

Gas Injection: Inert gas (like nitrogen or argon) is blown into the molten metal.

Stabilizing Foam: A rotating impeller helps distribute bubbles evenly.

Solidification: The Foam is cooled to retain its Structure.

Advantages:

No foaming agent needed

Can produce open-cell Foam (useful for filters)

Disadvantages:

Harder to control bubble size

Requires specialized equipment

Additive Manufacturing (3D Printing)

A modern approach where aluminum foam is 3D-printed layer by layer.

Process:

Designing Structure: A CAD model is created with a porous design.

3D Printing: Aluminum powder is fused using lasers (SLM – Selective Laser Melting).

Post-Processing: The part may be heat-treated for better strength.

Advantages:

Highly customizable

Complex geometries possible

Disadvantages:

Expensive

Limited to small-scale production

Which Method is Best for Aluminum Foam Casting?

For large-scale production → Casting Method

For high precision → Powder Metallurgy

For open-cell foam → Gas Injection

For custom designs → 3D Printing

Conclusion

Aluminum foam is manufactured using various methods, each with its advantages and disadvantages. The choice depends on cost, required properties, and production scale. Whether through casting, powder metallurgy, gas injection, or 3D Printing, aluminum foam continues to revolutionize industries with its lightweight and strong Structure.