Quartz glass plates are made of highly durable and transparent materials from pure quartz. They are widely used in electronics, optics, and scientific research because of their ability to withstand high temperatures and their clarity. The manufacturing process of quartz glass plates includes various steps to ensure the final product is strong, pure, and of high quality. Let’s take a look at how these plates are made.

Step 1: Sourcing the Raw Material

The first step in manufacturing quartz glass plates is obtaining the raw material: natural quartz. Quartz is a mineral made primarily of silicon dioxide (SiO2), and it’s found in rocks and sand. To make quartz glass, manufacturers use natural quartz crystals or synthetic quartz powder purified to remove any impurities.

Step 2: Melting the Quartz

Once the quartz is sourced, it must be melted to form glass. This is done in high-temperature furnaces reaching up to 2,000°C (3,632°F). At these extremely high temperatures, the quartz crystals break down and become molten, allowing them to be shaped into glass.

This part of the process is called fusing, and it requires immaculate and controlled conditions to ensure that no impurities contaminate the quartz glass.

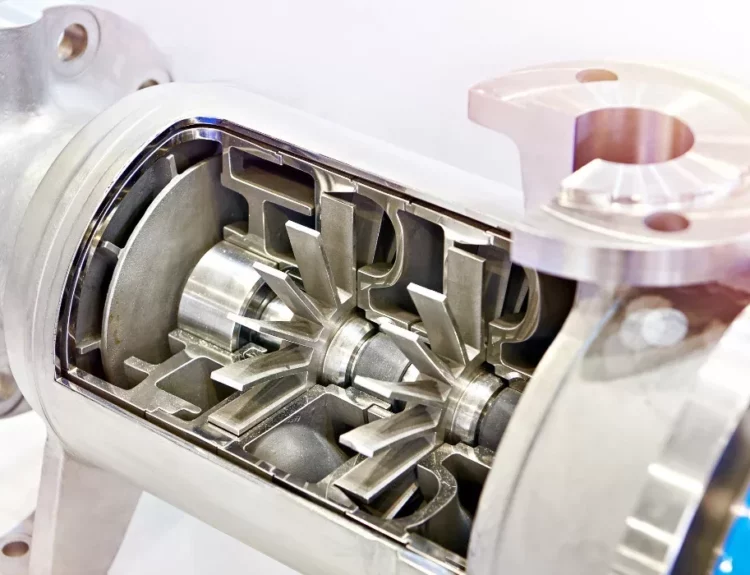

Step 3: Shaping the Quartz Glass

After the quartz has been melted, it is shaped into large, flat plates. There are different methods for doing this:

- Mold Casting: In this method, the molten quartz is poured into molds shaped like flat plates. The material cools and solidifies in the mold to form the quartz glass plate.

- Rolling: Another method is to use rollers to flatten the molten quartz into thin sheets. This technique allows manufacturers to control the thickness of the glass more precisely.

Both methods produce flat, smooth plates that can be used for many different purposes.

Step 4: Annealing the Glass

After shaping the quartz glass plates, they are still very hot and need to be cooled down slowly in an annealing process. During annealing, the glass plates are gradually cooled to room temperature. This step is essential because it removes internal stresses in the glass that can form when the material cools too quickly.

By annealing the quartz glass plates, manufacturers ensure that the plates are strong and won’t easily crack or break.

Step 5: Cutting and Polishing

Once the quartz glass has cooled, the plates are cut to the desired size. Specialized tools are used to cut the glass precisely because quartz is a hard material and can be challenging to shape.

After cutting, the edges of the glass plates are polished to smoothness. If optical clarity is needed, such as in lenses or scientific instruments, the surfaces are also polished.

Step 6: Quality Control

The last step in the quartz plate manufacturing process is quality control. Each quartz glass plate is inspected for defects, such as cracks, bubbles, or scratches. Because quartz glass is used in sensitive applications like electronics and scientific experiments, it must be of the highest quality. Any defects could affect its performance.

Best Quartz Glass Plate Manufacturers List

Manufacturers also check that the plates meet specific size and thickness requirements to ensure they are suitable for their intended use.

Conclusion

Manufacturing quartz glass plates involves sourcing pure quartz, melting it at high temperatures, shaping it into flat plates, and then cooling and cutting it to precise dimensions. This process ensures that the quartz glass is strong, heat-resistant, and highly transparent, making it perfect for use in optics, electronics, and research industries.

In short, making quartz glass plates is a complex process that turns raw quartz into a highly durable material used for advanced applications in many fields.