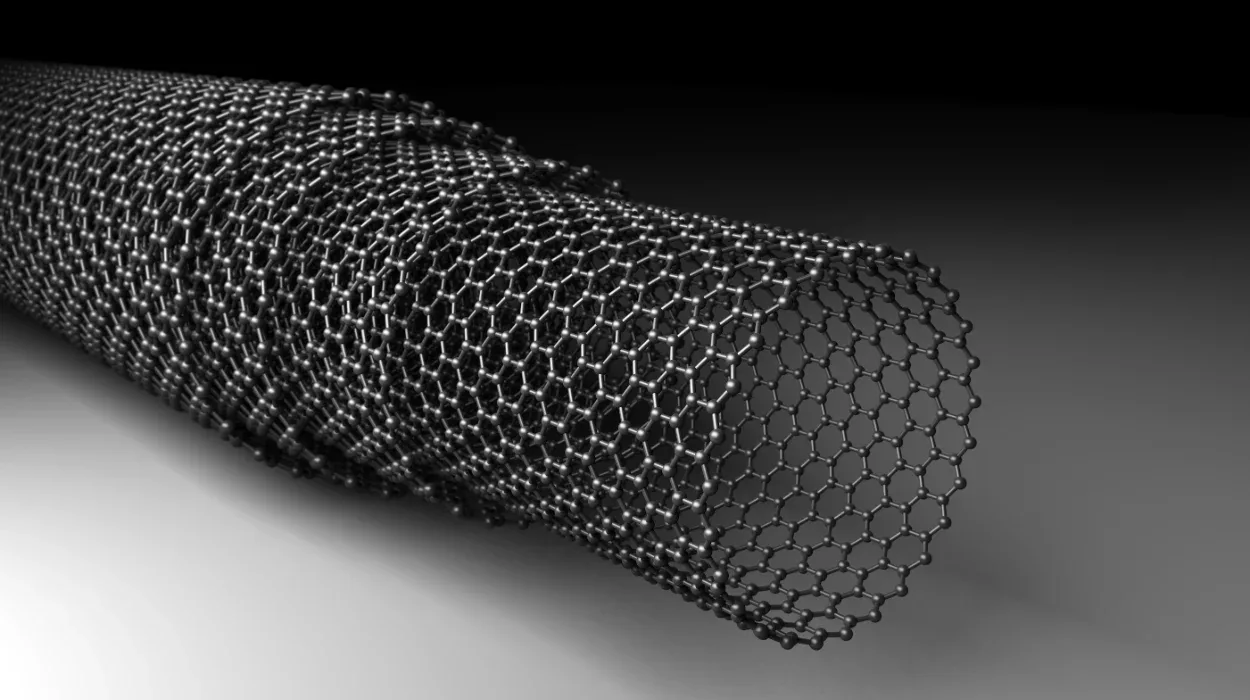

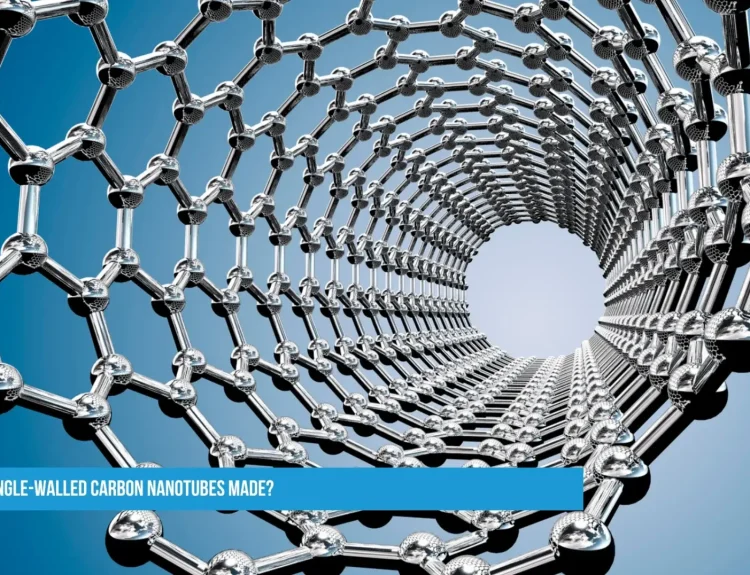

Multi-walled carbon nanotubes (MWCNTs) are not just tiny, tube-like structures made of multiple layers of carbon atoms. They are marvels of nature, possessing extraordinary properties such as high strength, electrical conductivity, and thermal stability. These unique characteristics make MWCNTs a captivating subject of study and a valuable tool in various scientific and industrial applications. This article will guide you on how to work with MWCNTs in a simple and easy-to-understand way.

What are Multi-Walled Carbon Nanotubes?

Multi-walled carbon nanotubes are composed of several concentric layers of graphene rolled into cylindrical shapes. These layers are nested inside one another, like the rings of a tree trunk. MWCNTs can have different diameters and lengths, but they are all incredibly small—thousands of times thinner than a human hair.

Working with Multi-Walled Carbon Nanotubes

1. Preparation and Handling:

- Wear Protective Gear: Always wear gloves, a lab coat, and a dust mask or respirator when handling MWCNTs. These precautions help prevent inhalation or skin contact, as MWCNTs can be harmful if they enter the body.

- Work in a Ventilated Area: Use a fume hood or a well-ventilated workspace to avoid inhaling particles. This ensures a safe working environment.

2. Dispersion:

- Choose a Solvent: To work with MWCNTs, you often need to disperse them in a liquid. Common solvents include water, ethanol, and dimethylformamide (DMF).

- Use Surfactants: Adding a surfactant (a substance that reduces surface tension) helps disperse MWCNTs evenly in the solvent. Examples include sodium dodecyl sulfate (SDS) and Triton X-100.

- Sonication: Place the MWCNTs and solvent mixture in an ultrasonic bath or use a probe sonicator to break up clumps and achieve uniform dispersion. This process usually takes 10-30 minutes, depending on the amount and type of MWCNTs.

3. Functionalization:

- Chemical Treatment: Sometimes, you need to modify the surface of MWCNTs to improve their compatibility with other materials. This process is called functionalization. Common methods include acid treatment (using sulfuric and nitric acids) and plasma treatment.

- Attach Functional Groups: Functionalization involves attaching various chemical groups (e.g., carboxyl, hydroxyl) to the surface of MWCNTs. These groups make the MWCNTs more reactive and more accessible to mix with other substances.

4. Incorporation into Composites:

- Mix with Polymers: MWCNTs can be mixed with polymers to enhance their properties. For example, adding MWCNTs to plastic can make it stronger and more conductive.

- Ensure Even Distribution: To achieve the best results, ensure that MWCNTs are evenly distributed throughout the polymer matrix. This can be done by mechanical mixing, extrusion, or using high-shear mixers.

5. Characterization:

- Microscopy: Use scanning electron microscopy (SEM) or transmission electron microscopy (TEM) to observe the structure and dispersion of MWCNTs.

- Spectroscopy: Techniques like Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) help analyze the chemical composition and functionalization of MWCNTs.

- Thermal Analysis: Differential Scanning Calorimetry, also known as (DSC) and Thermogravimetric Analysis, also known as (TGA) can be used to study the thermal properties and stability of MWCNTs and their composites.

6. Applications:

- Electronics: MWCNTs make conductive films, sensors, and transistors.

- Energy Storage: They are used in batteries and supercapacitors to enhance energy storage capacity and performance.

- Composite Materials: MWCNTs improve the mechanical properties of materials like plastics, metals, and ceramics.

- Medical Devices: They are used in drug delivery systems, imaging, and as scaffolds for tissue engineering.

7. Manufacturers of Multi-Walled Carbon Nanotubes:

Conclusion

Working with multi-walled carbon nanotubes involves careful preparation, handling, and dispersion. By following safety guidelines and using proper techniques, you can successfully incorporate MWCNTs into various applications, from electronics to medicine. These techniques, when mastered, will make you feel competent and skilled in working with this remarkable material. Their remarkable strength, conductivity, and versatility make them a valuable material in advancing science and technology.