Introduction

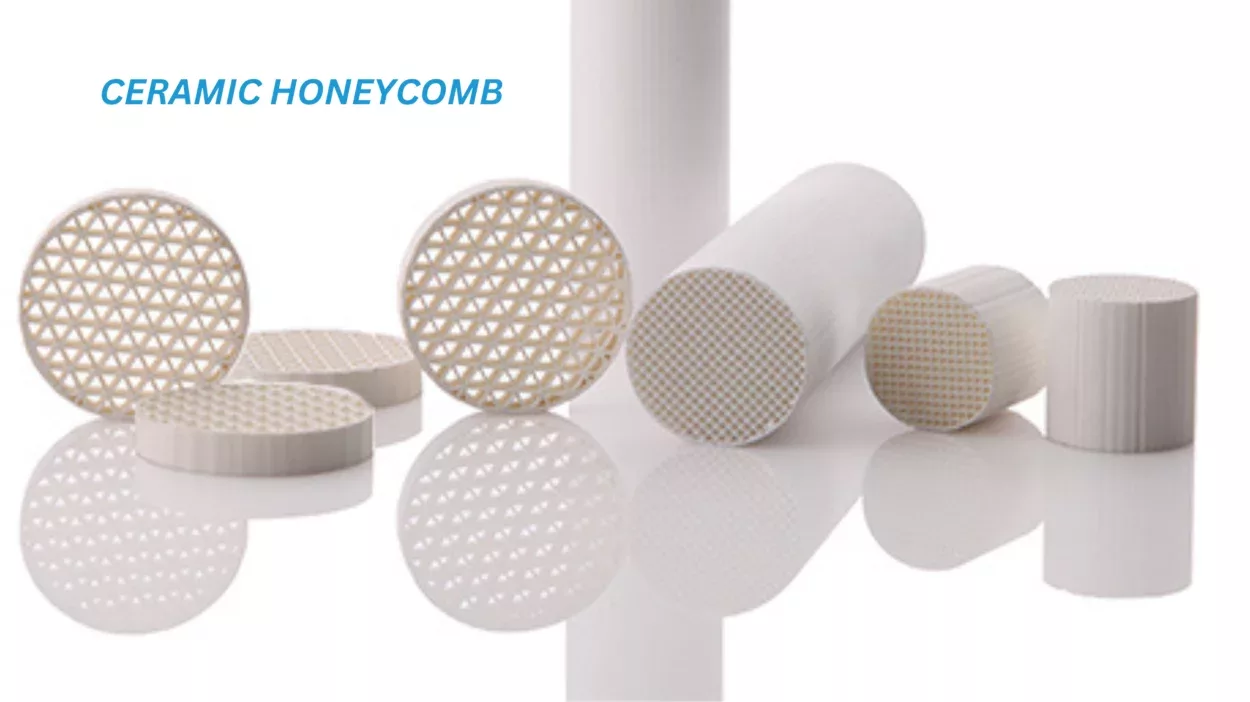

Ceramic honeycomb is a fascinating material used in various applications, from car exhaust systems to air and water purification devices. Its unique structure, resembling a beehive, gives it special properties that make it strong, durable, and efficient. This article will explain what ceramic honeycomb is, its mechanical properties, and why it is so durable, all in simple language.

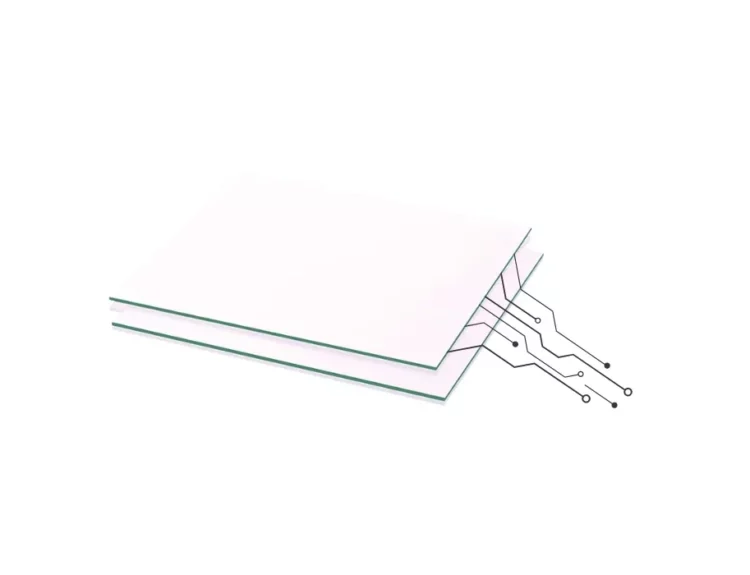

What is a Ceramic Honeycomb?

A ceramic honeycomb is made from ceramic materials like cordierite or alumina. It consists of many small, hollow cells arranged in a honeycomb pattern. This design gives the material a high surface area while keeping it lightweight. The honeycomb structure can be found in various sizes and shapes depending on its intended use.

Key Mechanical Properties

Strength

- What It Means: Strength refers to the ability of the ceramic honeycomb to withstand forces without breaking.

- Why It Matters: High strength is crucial for applications that expose the material to heavy loads or pressures, such as automotive catalytic converters.

Stiffness

- What It Means: Stiffness measures how much the material resists deformation when applied force.

- Why It Matters: A stiff material doesn’t bend or deform easily, making ceramic honeycomb ideal for structural applications where maintaining shape is essential.

Thermal Stability

- What It Means: Thermal stability is the ability of the ceramic honeycomb to maintain its properties at high temperatures.

- Why It Matters: This property is essential for applications like exhaust systems, where the material is regularly exposed to high temperatures.

Lightweight

- What It Means: Being lightweight means that ceramic honeycomb has a low density.

- Why It Matters: Lightweight materials are easier to handle and can improve the efficiency of vehicles and other systems by reducing overall weight.

Durability of Ceramic Honeycomb

Resistance to Corrosion

- What It Means: Corrosion resistance is the ability to withstand damage caused by chemical reactions, often with gases or liquids.

- Why It Matters: Ceramic honeycomb’s resistance to corrosion makes it last longer in harsh environments, like car exhausts or industrial filters.

Thermal Shock Resistance

- What It Means: Thermal shock resistance is the capacity to endure sudden temperature fluctuations without fracturing or breaking.

- Why It Matters: This property is vital for materials that experience quick temperature changes, ensuring they don’t fail under stress.

Wear and Tear Resistance

- What It Means: Wear and tear resistance refers to how well the material withstands gradual damage from friction and use over time.

- Why It Matters: High resistance to wear and tear ensures that ceramic honeycomb maintains its performance over a long period, even in demanding conditions.

Applications Benefiting from Mechanical Properties and Durability

Automotive Industry

- Use Catalytic converters in car exhaust systems.

- Benefits: High thermal stability and corrosion resistance help convert harmful gases into less harmful emissions, while the lightweight nature improves fuel efficiency.

Environmental Technology

- Use: Air and water purification systems.

- Benefits: Durability and resistance to chemical corrosion make ceramic honeycomb ideal for filtering pollutants and contaminants.

Industrial Processes

- Use: Heat exchangers and kilns.

- Benefits: The ability to withstand high temperatures and thermal shock ensures efficient heat transfer and reliable performance in high-temperature processes.

Conclusion

Ceramic honeycomb is a remarkable material that combines strength, stiffness, thermal stability, and lightweight properties, making it suitable for many demanding applications. Its durability, including resistance to corrosion, thermal shock, and wear and tear, ensures long-lasting performance even in harsh environments. As technology advances, the use of ceramic honeycomb is likely to expand, bringing its benefits to even more applications and industries.

To purchase this product, please follow the link given below.

2-Shilpent