Introduction

3D printing, also known as additive manufacturing, has revolutionized how objects are designed and produced. It allows the creation of complex shapes with high precision. However, to improve the strength, conductivity, and durability of 3D-printed materials, scientists have turned to Multi-Walled Carbon Nanotubes (MWCNTs). These nanotubes are helping to create stronger and more advanced printed materials for various industries.

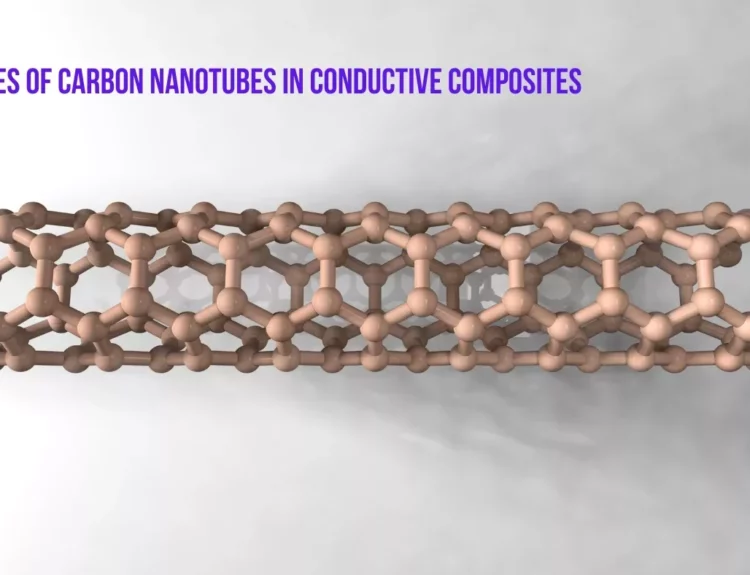

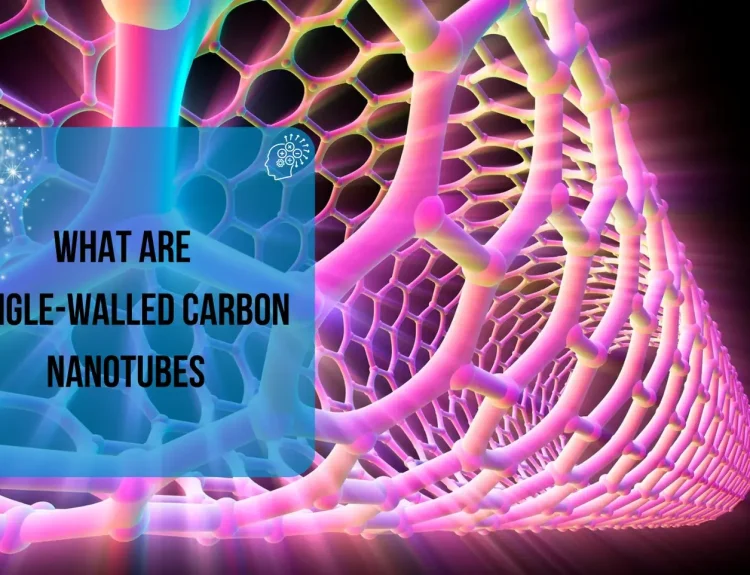

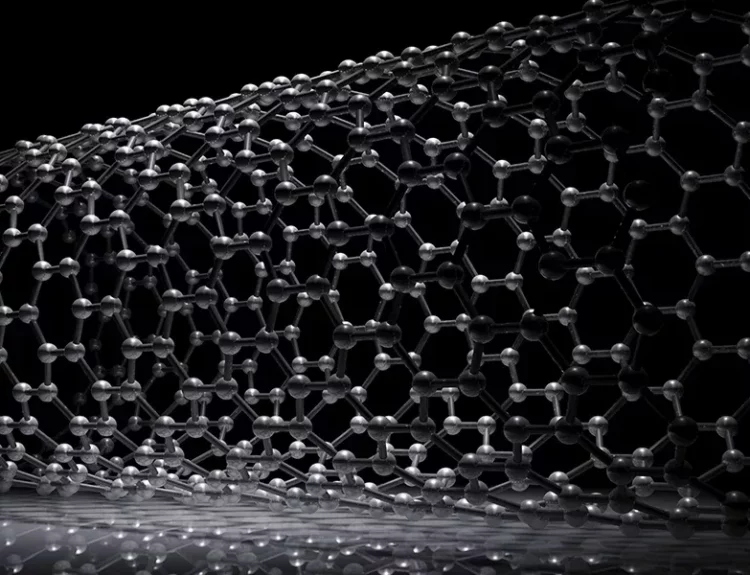

What Are Multi-Walled Carbon Nanotubes (MWCNTs)?

MWCNTs are tiny cylindrical structures made of multiple layers of carbon atoms. They have exceptional electrical conductivity, high strength, and lightweight properties, making them ideal for advanced applications. When added to 3D printing materials, MWCNTs enhance the mechanical and electrical properties of the printed objects.

How MWCNTs Improve 3D Printing

Enhancing Strength and Durability

- MWCNTs improve the mechanical properties of printed objects, making them stronger, more flexible, and impact-resistant.

- They are especially useful in aerospace, automotive, and construction industries, where durable materials are essential.

Improving Electrical Conductivity

- Traditional 3D printing materials like plastic are not conductive. Adding MWCNTs turns them into conductive materials, enabling the production of electronic circuits, sensors, and flexible devices.

- This is important for wearable technology and medical devices that require conductivity.

Enhancing Heat Resistance

- MWCNTs can withstand high temperatures, making them useful for heat-resistant 3D-printed parts.

- Industries like aerospace and automotive benefit from this, as they need materials that can endure extreme conditions.

Better Printability and Layer Adhesion

- Adding MWCNTs helps improve the flow and bonding of printing materials.

- This results in smoother prints, better layer adhesion, and improved print quality.

Buy Multi Walled Carbon Nanotube

Applications of MWCNTs in 3D Printing

- Aerospace and Automotive: Creating lightweight yet strong components.

- Electronics: Printing conductive circuits and smart devices.

- Medical Industry: Developing biocompatible implants and prosthetics.

- Energy Storage: Enhancing batteries and supercapacitors.

- Construction: Producing high-strength 3D-printed structures.

Challenges and Future Possibilities

While MWCNTs offer many benefits, some challenges need to be addressed:

- Dispersion Issues: Ensuring even mixing of MWCNTs in printing materials.

- Cost: MWCNTs are expensive, which can increase production costs.

- Safety Concerns: Research is ongoing to ensure safe handling and environmental impact.

Despite these challenges, MWCNTs are shaping the future of 3D printing, making it more advanced and efficient. As research continues, we can expect new breakthroughs in additive manufacturing that will change the way industries create materials and products.

Conclusion

MWCNTs are opening new possibilities in 3D printing, allowing for stronger, more conductive, and heat-resistant materials. From aerospace to medical applications, these nanotubes are transforming the way objects are manufactured. With continuous advancements, MWCNTs in 3D printing will play a vital role in the future of technology and industry.