Imagine printing a computer circuit as easily as you print a birthday card. Or wearing a bright t-shirt that monitors your health, or putting a flexible screen in your pocket—not a rigid phone, but a literal, rollable screen. This isn’t just science fiction; it’s the future being built today, and it’s being written in graphene ink.

First, what is Graphene?

Before we discuss the ink, we must first meet the superstar material: graphene.

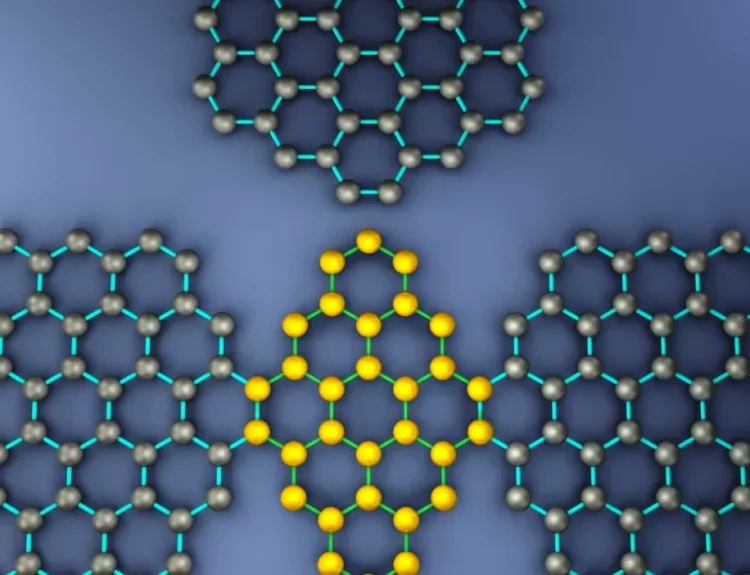

Graphene is a single, skinny layer of carbon atoms arranged in a perfect honeycomb pattern. It’s not just thin; it’s the thinnest material known to science—only one atom thick. But don’t let its fragility fool you. Graphene is a superhero of materials:

It’s powerful (over 200 times stronger than steel).

It’s extremely flexible and stretchable

It’s the most conductive material known for both electricity and heat.

For years, scientists have been excited about the potential of graphene. The major challenge has been figuring out how to mass-produce it and integrate it into real-world products. This is where graphene ink comes in.

So, what is Graphene Ink?

Simply put, graphene ink is a specially formulated “paint” or “paste” that contains tiny flakes of graphene suspended in a liquid. Think of it like glitter in glue, but where the “glitter” is microscopic sheets of super-conductive carbon.

This ink can be loaded into printers—not your standard office printer, but advanced ones like inkjet, screen, or even 3D printers. This allows manufacturers to “print” electronic circuits directly onto various surfaces.

Why is This a “Revolution”?

Printing with graphene ink is a game-changer compared to the methods used to make electronics today. Traditional electronics rely on rigid silicon chips and circuit boards, which are created through complex, expensive, and energy-intensive processes in giant factories.

Graphene ink flips this model on its head. Here’s why:

It’s Cheap and Scalable: Once you can produce the ink, you can print circuits quickly and affordably on a massive scale, similar to printing newspapers. This significantly reduces the cost of manufacturing electronics.

It’s Flexible and Durable: Unlike the brittle materials used in today’s circuits, graphene ink can be printed on flexible plastics, fabrics, and even paper. The circuits can bend, stretch, and twist without breaking. This is the key to wearable technology and foldable devices.

It’s Versatile: You can print electronics on almost anything. This opens up a world of possibilities that were previously impossible.

What Can We Actually Do with Graphene Ink?

The applications are where the revolution becomes real. We’re talking about:

Wearable Health Monitors: Instead of a bulky smartwatch, imagine a lightweight, washable patch printed directly onto fabric that continuously tracks your heart rate, hydration, or muscle activity. Athletes and doctors can obtain real-time data without the need for uncomfortable equipment.

Smart Packaging: A milk carton could have a printed expiration sensor that changes color when the product spoils. A shipping label could have a printed temperature log to show if your frozen food thawed during delivery.

Massive, Flexible Sensors: Scientists can print enormous, ultra-thin sensors on plastic sheets to cover entire walls or windows, turning them into touch-sensitive surfaces or environmental monitors.

Printed RFID Tags: Cheap, disposable electronic tags could be printed directly on product packaging for inventory tracking, making logistics faster and more efficient.

The Future of Solar Power: Graphene ink could be used to print lightweight, flexible, and cheap solar cells onto surfaces like tents, car roofs, or even clothing, turning them into portable chargers.

What’s the Catch?

No technology is perfect from the start. The main challenges for graphene ink are:

Perfecting the Recipe: Getting the right concentration and size of graphene flakes in the ink for optimal conductivity is tricky.

Printing Precision: Ensuring every printed circuit is perfectly accurate is vital for complex electronics.

Integration: Figuring out how to combine these printed circuits with traditional power sources and computer chips.

However, researchers and companies are solving these problems at a rapid pace.

The Bottom Line

Graphene ink is more than just a new material; it’s a new way of thinking about manufacturing. It promises a future where electronics are no longer rigid, expensive, and confined to a circuit board. Instead, they will be flexible, cheap, and integrated seamlessly into the fabric of our everyday lives, literally.