In the critical moments of a collision—whether in a car, an aircraft, or on a battlefield—the most important factor is energy management. That violent, destructive force must be absorbed, dissipated, and controlled to preserve what matters most: human life and critical systems.

For decades, the solution was a trade-off: add more solid, heavy material to crumple and bear the brunt of the force. But what if you could achieve unparalleled protection with a fraction of the weight? This is not a theoretical question. The revolution is here, and it’s filled with voids. It’s called metal foam.

The Physics of Protection: Why Empty Space is Stronger Than Steel

At first glance, metal foam may seem like a paradox. How can a material that is up to 80% air be so effective at absorbing a powerful impact? The answer lies in its unique failure mechanism.

Unlike a solid piece of metal that bends or fractures under stress, metal foam is designed to collapse in a controlled and predictable manner. When a crushing force is applied, the microscopic cell walls within the foam begin to buckle and fracture in a sequential, progressive wave.

This process converts the massive kinetic energy of the impact into other forms of energy:

- Plastic Deformation Energy: The energy required to bend and crush the metal cell walls permanently.

- Fracture Energy: The energy required to break those cell walls.

- Sound and Heat Energy: The byproducts of this violent, microscopic collapse.

The result is a near-constant plateau stress—meaning the foam absorbs a tremendous amount of energy while maintaining a relatively consistent reaction force. This crush zone acts as a perfect, predictable buffer, dramatically decelerating whatever it is protecting.

Transforming Industries: Metal Foam in Action

The Automotive Crumple Zone 2.0

Traditional car crumple zones are engineered to fold in a specific sequence. By filling key sections of these zones with aluminum foam, engineers can create a “tunable” system that absorbs up to **three times more energy** per unit weight than steel.

The Result: A lighter vehicle with better fuel efficiency and a passenger cabin that experiences significantly lower G-forces during a crash. For electric cars, there are two significant benefits: reducing weight increases the vehicle’s range, and enhanced crash safety protects the high-voltage battery pack.

The Indestructible Black Box

Aircraft flight data recorders, commonly known as black boxes, must endure extreme impacts and fires. By encasing them in metal foam, we can create a nearly impenetrable shield. The foam crushes, dissipating the energy that would otherwise shatter the critical memory unit inside, ensuring the data survives to tell the story.

Blast Mitigation for a Safer World

In defense and security, the threat from blasts is immense. Integrating composite panels with a metal foam core into vehicle hulls and protective structures significantly reduces the force transmitted from a landmine or IED explosion. The foam core effectively absorbs the shockwave, protecting the occupants from its entire, lethal effect.

Saper Smart Infrastructure

From protective barriers on race tracks to sacrificial cores in high-speed train couplers, metal foam is being deployed wherever a predictable, high-energy impact poses a risk. It’s the ultimate sacrificial material, designed to be destroyed so that everything else isn’t.

The Tecklogik Advantage: Engineering the Void

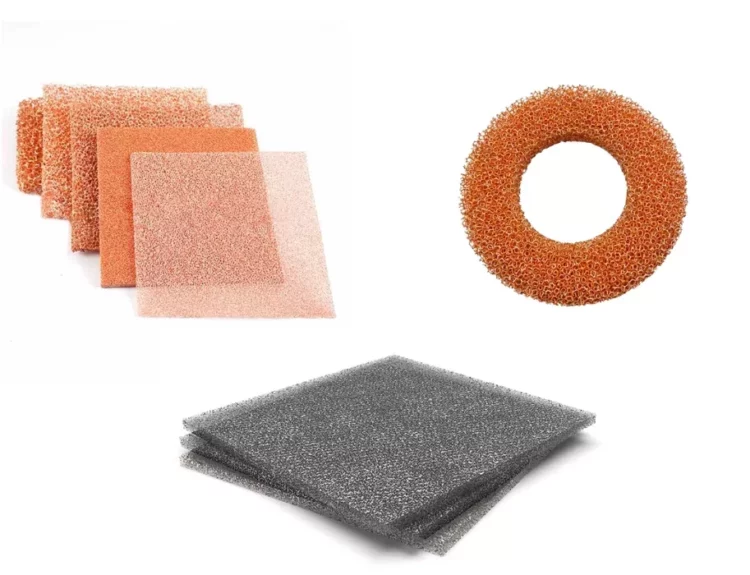

Not all metal foams are created equal. The key to its performance lies in the precise control of its internal architecture:

- Pore Size & Distribution: Consistent, controlled pore sizes ensure predictable, uniform collapse.

- Density Gradient: We can design foams with varying densities in different areas, creating a tuned absorber that effectively manages complex, multi-stage impacts.

- Base Material: Aluminum, titanium, and other alloys can be foamed, allowing us to match the material to the specific environmental and strength requirements.

Conclusion: The Future is Light, Safe, and Porous

The era of solving safety problems solely by adding brute mass is over. Metal foam represents a significant advancement in material science, showing that intelligently designed structures can outperform traditional solid materials in terms of weight. It acts as a silent yet resilient protector, sacrificing itself with remarkable efficiency.

This innovation goes beyond just enhancing strength; it also focuses on integrating intelligence into materials. And as this technology continues to evolve, the very definition of impact protection is being rewritten—one tiny, metallic pore at a time.