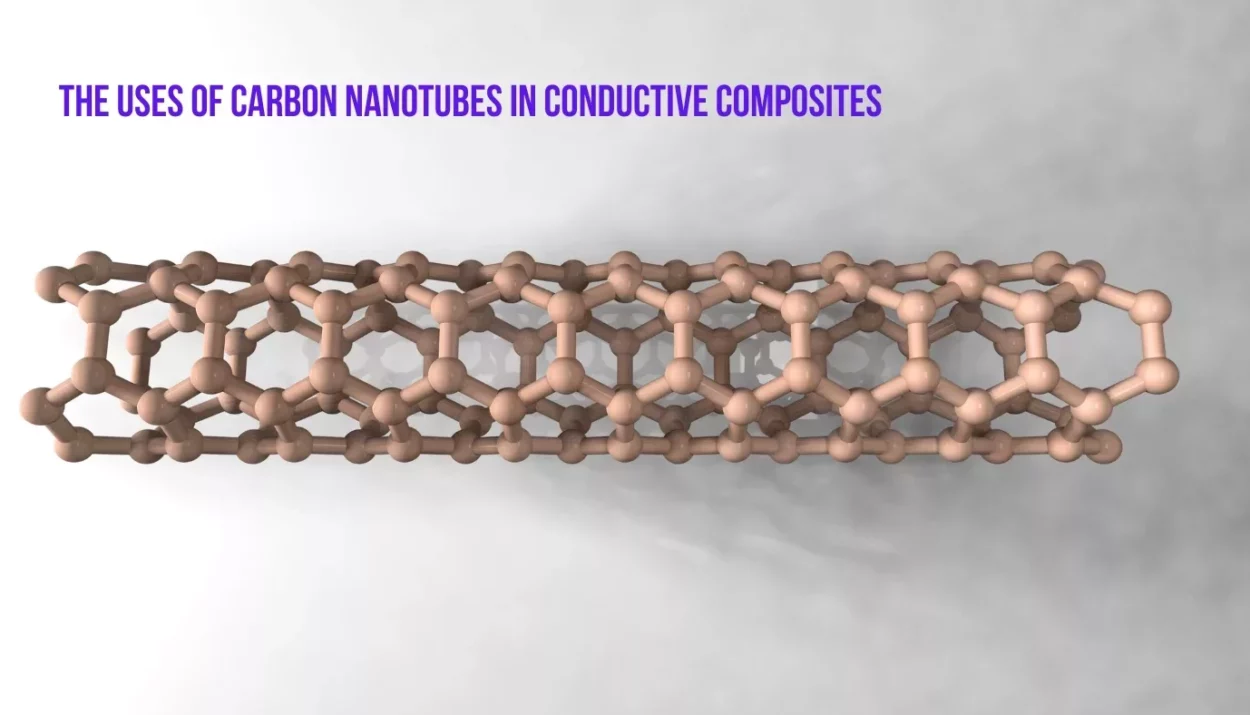

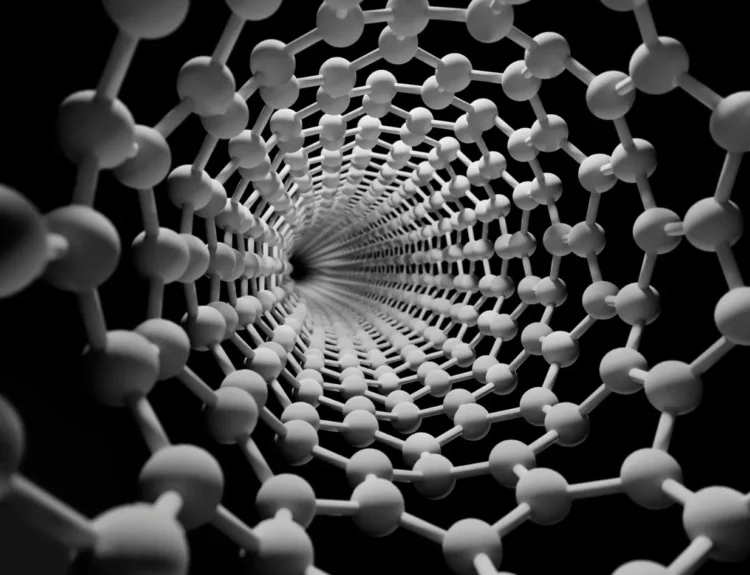

Carbon nanotubes (CNTs) are a revolutionary material that transforms how we design conductive composites. These tiny tube-shaped structures, made of carbon atoms, are robust, lightweight, and excellent conductors of electricity and heat. Due to their unique properties, CNTs are increasingly used in conductive composites for various industries.

What Are Conductive Composites?

Conductive composites combine a base material (such as plastic or polymer) with a conductive filler. These composites allow the final product to conduct electricity or heat while retaining the base material’s flexibility, durability, or other desirable properties. Carbon nanotubes are one of the most effective fillers for making such composites.

Why Use Carbon Nanotubes in Conductive Composites?

Carbon nanotubes offer several advantages when used as fillers:

- High Electrical Conductivity: CNTs provide excellent electrical pathways, making the composite highly conductive.

- Lightweight: CNTs add minimal weight to the composite, which is essential for applications in aerospace and electronics.

- Mechanical Strength: Adding CNTs enhances the overall strength and durability of the composite material.

- Thermal Conductivity: CNTs improve heat dissipation, crucial for devices that generate heat during operation.

Buy Carbon Nanotubes

- Single Walled Carbon Nanotube | Multi Walled Carbon Nanotube

- Single Walled Carbon Nanotube | Multi Walled Carbon Nanotube

Applications of CNT-Based Conductive Composites

- Electronics CNT-based conductive composites are used in flexible circuits, touchscreens, and wearable devices. Their high conductivity and flexibility make them ideal for modern electronics.

- Aerospace In the aerospace industry, CNT composites create lightweight, strong materials that can conduct electricity. This is especially useful for shielding aircraft from electromagnetic interference.

- Automotive Automobiles require strong and conductive materials for components like sensors and batteries. CNT composites help achieve these goals while reducing weight.

- Energy Storage Batteries and supercapacitors benefit from CNT composites because they enhance energy storage and conductivity. This leads to more efficient and longer-lasting energy solutions.

- Industrial Applications CNT composites are used in anti-static coatings, electromagnetic shielding, and conductive adhesives, which are essential in manufacturing and assembly processes.

How Are CNT-Based Conductive Composites Made?

- Dispersion: Carbon nanotubes are dispersed into the base material, ensuring even distribution. This is critical for achieving uniform conductivity.

- Mixing: The CNTs and base material are mixed using melt blending or solution casting techniques.

- Molding and Curing: The mixture is shaped into the desired form and cured to set its structure.

- Testing: The final composite is tested for conductivity, strength, and other required properties.

Challenges in Using CNTs for Conductive Composites

- Cost: High-purity CNTs can be expensive, affecting the composite’s overall cost.

- Dispersion Issues: Ensuring even dispersion of CNTs in the base material is technically challenging.

- Compatibility: CNTs must be compatible with the base material to achieve optimal results.

Conclusion

Using carbon nanotubes in conductive composites has created new possibilities for creating advanced materials. With their exceptional electrical, thermal, and mechanical properties, CNT-based composites are paving the way for innovations in electronics, energy, aerospace, and beyond. As technology evolves, their production and application challenges will likely be overcome, making CNT composites even more accessible and impactful.