Introduction

Carbon nanotubes (CNTs) have taken the scientific and engineering communities by storm with their incredible properties and a wide array of potential applications. Their outstanding electrical conductivity, mechanical strength, and thermal stability have made them a focal point of research and development across various industries. This article explores the intriguing world of carbon nanotube production, shedding light on the methods and challenges associated with manufacturing these tiny but mighty structures.

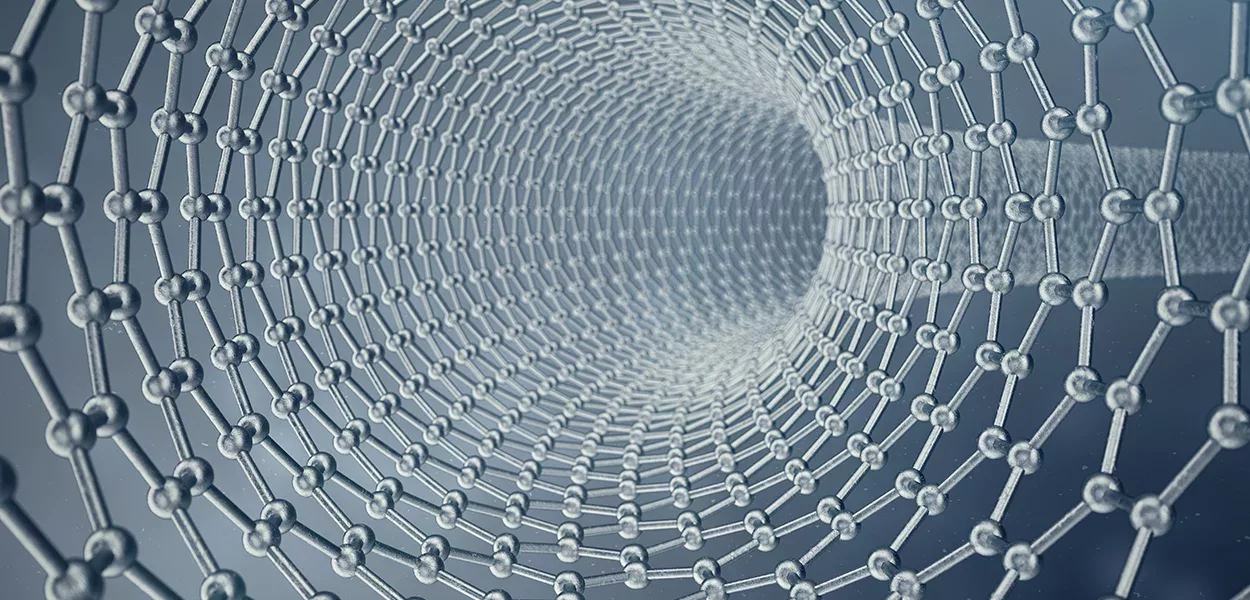

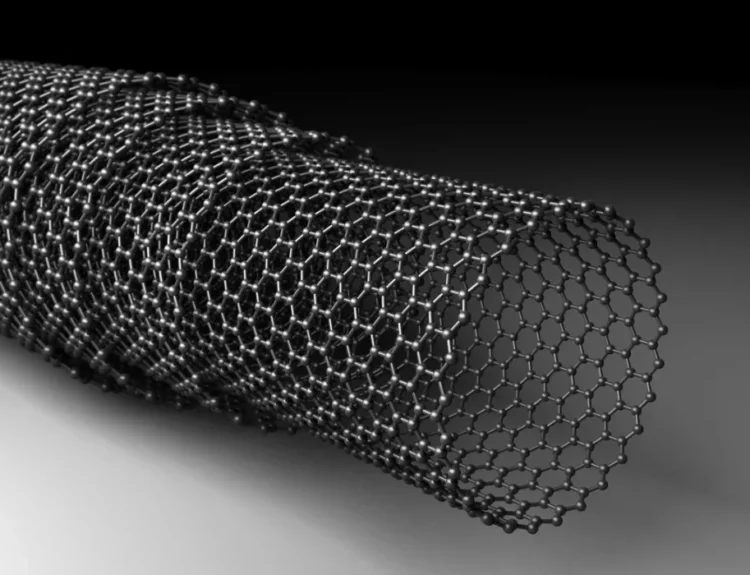

Understanding Carbon Nanotubes

Carbon nanotubes are cylindrical nanostructures comprised of carbon atoms in a hexagonal lattice, forming a tube-like structure. These nanotubes come in various forms, with Single-Walled Carbon Nanotubes (SWCNTs) comprised of a single layer and Multi-Walled Carbon Nanotubes (MWCNTs) composed of multiple concentric layers. The method of production often determines the type and quality of CNTs obtained.

Production Methods

There are several methods for producing CNTs, with each having its unique advantages and challenges:

- Chemical Vapor Deposition (CVD): This widely used method involves the decomposition of hydrocarbon gases (like methane) on a metal catalyst substrate, such as iron, cobalt, or nickel. CNTs grow on the substrate as carbon atoms are deposited. CVD allows for precise control over CNT properties but can be complex and costly.

- Arc Discharge: In this technique, a high-voltage electrical discharge is created between two graphite electrodes in an inert gas (usually helium). The intense heat generated in the discharge process results in CNT formation. Arc discharge is known for its efficiency in producing CNTs, but it can yield a mixture of CNTs and other carbon materials.

- Laser Ablation: Laser ablation involves using a high-power laser beam to vaporize a carbon target in a controlled atmosphere. The vaporized carbon condenses to form CNTs. This method produces high-purity CNTs, but it can be costly as it is needed advanced laser systems.

Challenges in CNT Production

The production of carbon nanotubes, while promising, comes with several challenges:

- Cost: Many CNT production methods can be expensive, limiting widespread adoption. Reducing production costs is a priority for making CNTs more accessible for various applications.

- Contamination: Impurities and non-tubular carbon structures can be present in CNT batches. Extensive purification processes are required to obtain high-purity CNTs suitable for many applications.

- Scale-up: Scaling up the production of CNTs while maintaining quality and consistency remains a challenge. Developing scalable and cost-effective production methods is crucial for industrial applications.

- Safety and Environmental Concerns: The production and handling of CNTs may raise safety and environmental concerns. Proper safety measures and responsible handling are essential to address these issues.

Applications of Carbon Nanotubes

Despite the challenges, CNTs have found applications in a wide range of industries, including:

- Electronics: CNTs are used to develop high-performance transistors, conductive inks, and flexible electronics due to their exceptional electrical conductivity.

- Materials Science: CNTs reinforce polymers, ceramics, and metals, enhancing their mechanical strength, thermal conductivity, and electrical properties.

- Energy Storage: CNTs are used in advanced supercapacitors and lithium-ion batteries, enabling faster charging and higher energy densities.

- Sensors: CNTs are employed in various sensor technologies, including gas sensors, biosensors, and strain sensors, thanks to their high surface area and sensitivity to environmental changes.

- Medical Applications: Functionalized CNTs have shown promise in drug delivery systems and diagnostic devices.

- Catalysis: CNTs are efficient catalyst supports for various chemical reactions, including hydrogenation and oxidation.

Conclusion

The world of carbon nanotube production is dynamic and full of promise. As research and development efforts continue to refine production methods and address challenges such as cost and scalability, CNTs are poised to revolutionize various industries. The remarkable properties of these tiny structures have the potential to drive innovation in fields ranging from electronics to energy storage, materials science, and beyond. As the science and technology of carbon nanotubes advance, we can expect to witness new and groundbreaking applications that harness the power of these remarkable nanomaterials.

We recommend Techinstro to purchase Carbon Nanotubes products.