When it comes to creating strong and resilient materials, science is constantly pushing the boundaries. One of the exciting areas of research involves the use of MgO nanoparticles. These tiny but mighty particles are changing the game in ceramics and composite materials. This article will explore how these nanoparticles affect materials’ thermal and mechanical properties and what this means for various applications.

Meet the MgO Nanoparticles

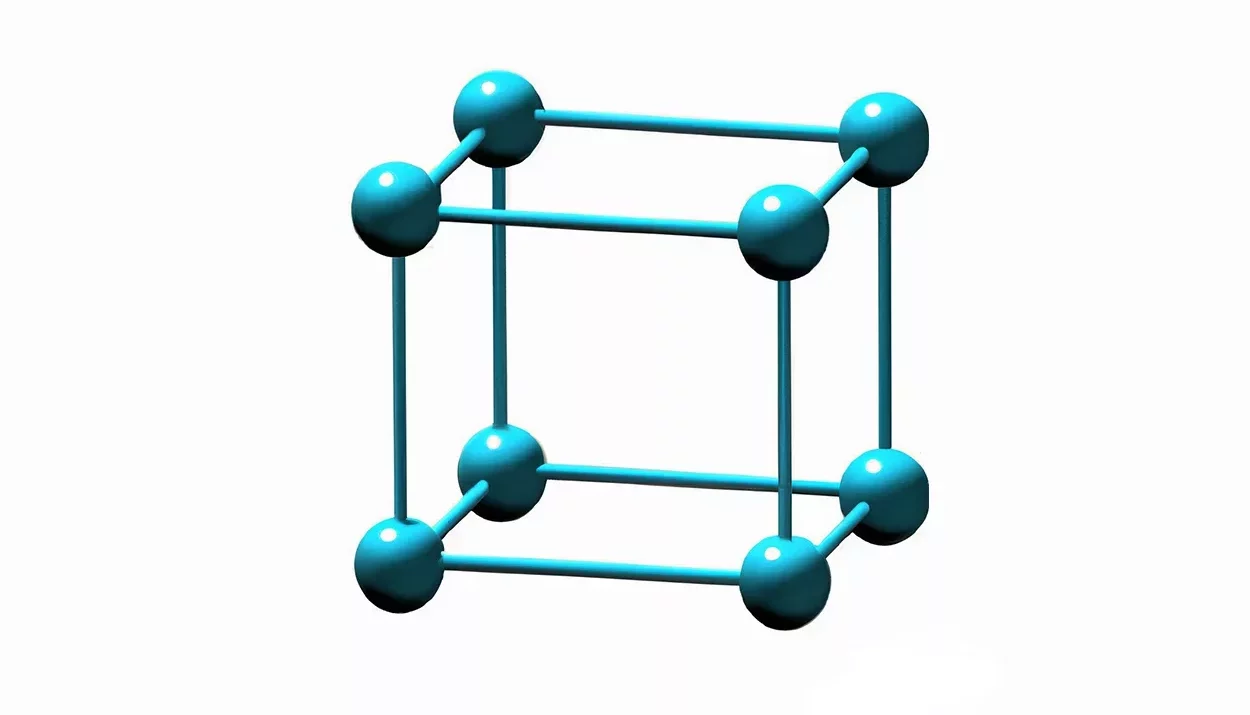

Before we dive into the world of ceramics and composites, let’s get to know our main characters: MgO nanoparticles. “MgO” stands for magnesium oxide, a compound of magnesium and oxygen. But when we talk about “nanoparticles,” we’re talking about super tiny particles, thousands of times smaller than the width of a human hair. These nanoparticles are like the secret agents of the materials world, working silently but effectively to improve the properties of ceramics and composites.

The Thermal Superpowers

- Improved Thermal Conductivity: One of the superpowers of MgO nanoparticles is their ability to enhance thermal conductivity in materials. This means they help materials conduct heat better. This can lead to better heat distribution and improved resistance to temperature extremes in ceramics.

- Thermal Stability: MgO nanoparticles can also make materials more stable at high temperatures, which is crucial in applications like aerospace, where materials must withstand extreme conditions.

The Mechanical Marvels

- Increased Strength: These nanoparticles act as reinforcements for materials. Adding to ceramics or composites makes them stronger and more resistant to breaking or cracking. This added strength is especially valuable in construction and engineering.

- Improved Durability: Materials containing MgO nanoparticles are extra resistant and durable to wear and tear. This makes them ideal for use in products that experience stress, like car parts or sports equipment.

Applications in Ceramics

- Advanced Cookware: Ceramic cookware containing MgO nanoparticles can distribute heat more evenly, making your cooking experience better and more efficient.

- High-Performance Tiles: Tiles with improved strength and heat resistance can be used in kitchens, bathrooms, and even industrial settings.

Applications in Composites

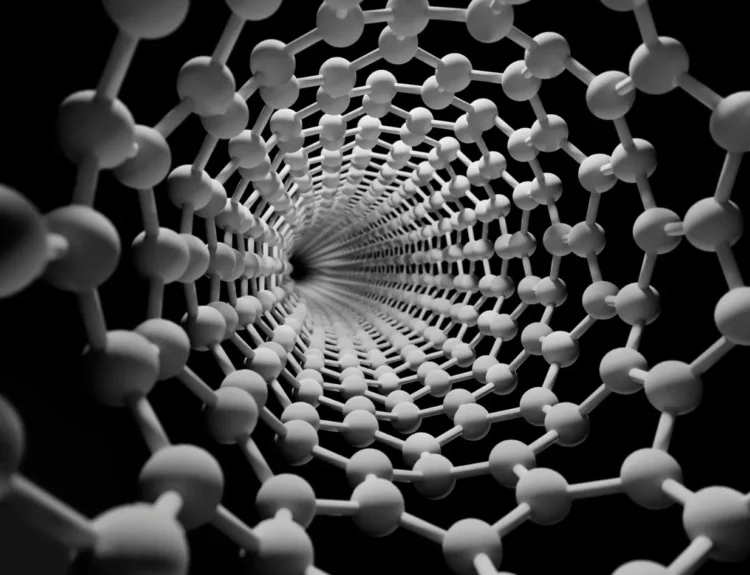

- Aerospace Components: Lightweight yet strong composite materials with MgO nanoparticles can be used in aircraft, rockets, and satellites.

- Automobile Parts: Enhanced composites can make car parts lighter, improving fuel efficiency and safety.

Challenges and Future Outlook

While the potential of MgO nanoparticles is exciting, researchers are also studying their safety and environmental impact. It’s essential to balance innovation and responsibility when using these materials.

As scientists are in the process of unlocking the secrets of MgO nanoparticles, we expect to see even more remarkable advancements in ceramics and composites. These tiny warriors are helping us create materials that are stronger, more durable, and better equipped to tackle the challenges of the modern world. The future of materials science is indeed an exciting one!