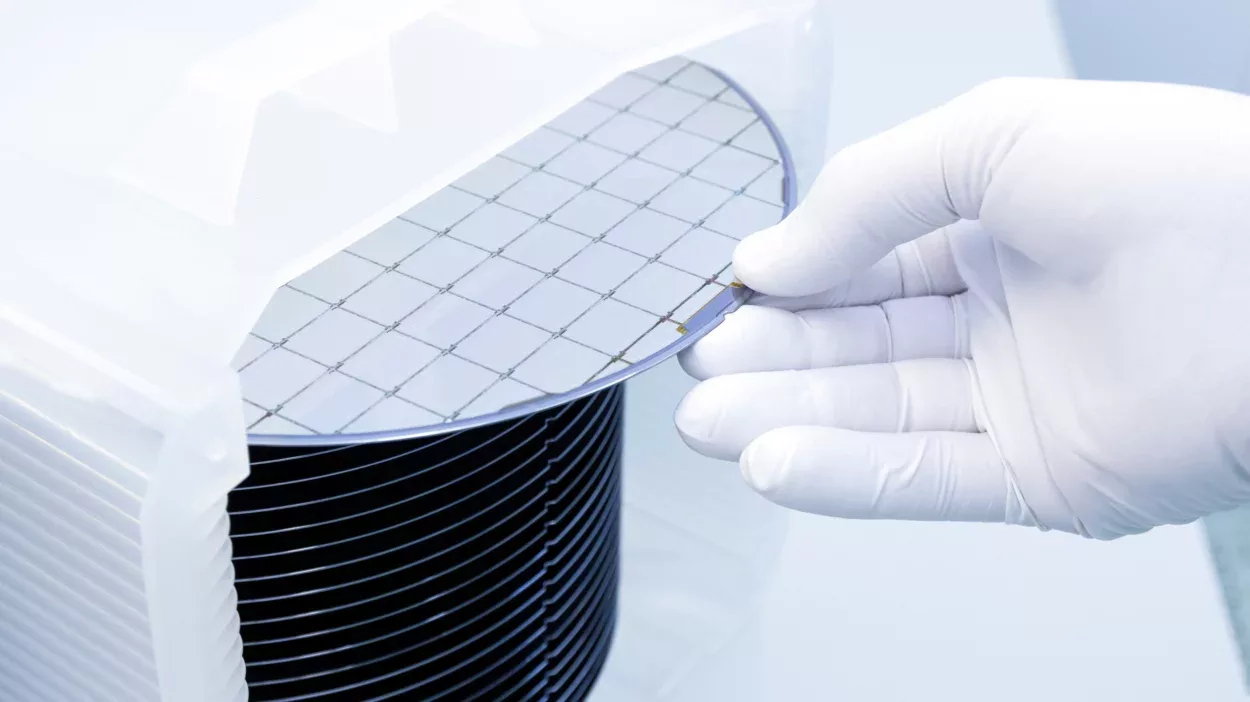

A silicon wafer is a slice of silicon crystal used as a substrate for microelectronic devices. Silicon is the most common material used to manufacture semiconductors because it is relatively easy to work with, has good electrical properties, and is abundant in the Earth’s crust.

How Silicon Wafers Are Made

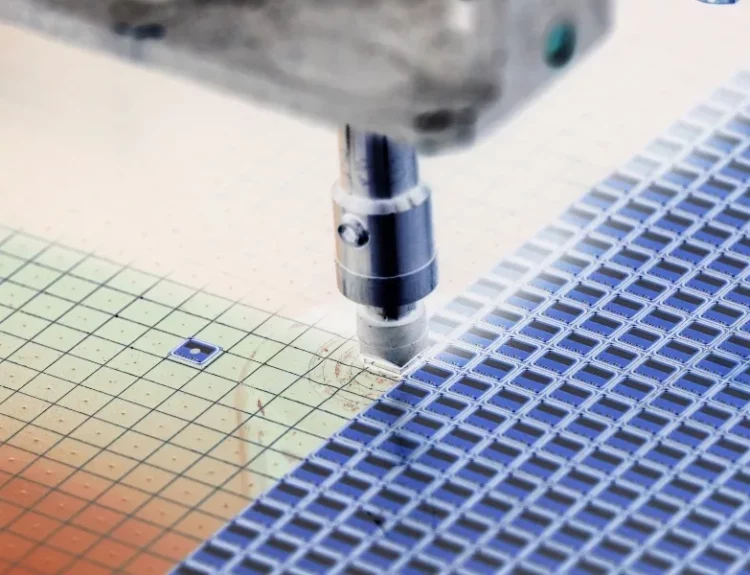

Making silicon wafers starts with silica mining, which is then purified and converted into highly pure polycrystalline silicon. This silicon is then melted and formed into a single, cylindrical silicon crystal through Czochralski growth. The cylindrical crystal, a “boule,” is then sliced into thin wafers using a precise cutting technique. The wafers are then polished to a mirror finish, creating the smooth, flat surfaces necessary to fabricate microelectronic devices.

Uses and Applications

Silicon wafers are the foundation of the electronics industry. They are used to create a wide variety of electronic components, including:

- Integrated Circuits (ICs): Also known as microchips, these are used in computers, smartphones, and other digital devices. A tiny silicon chip contains millions or billions of transistors and other electronic components.

- Solar Cells: Silicon wafers produce photovoltaic cells, which convert sunlight into electricity. This area is growing as the world moves towards more sustainable energy sources.

- Sensors: Silicon-based sensors are used in many applications, from automotive to environmental monitoring, due to their sensitivity and reliability.

Future Applications

As technology advances, the role of silicon wafers is expanding into new and exciting areas:

- Quantum Computing: Silicon wafers could play a vital role in developing quantum computers, which promise to exceed the capabilities of today’s classical computers vastly.

- Internet of Things (IoT): As more everyday objects connect to the internet, there’s an increasing need for small, efficient chips made from silicon wafers to power these devices.

- Flexible Electronics: Research is underway to develop flexible silicon wafers for use in wearable technology and bendable electronic devices.

- Advanced Sensors: Silicon wafers will be used to develop more advanced sensors for applications in healthcare, such as implantable devices that monitor vital signs or deliver drugs.

Conclusion

Silicon wafers are at the heart of modern electronics and will continue to play a crucial role as we move into the future. Their versatility and the ongoing innovations in silicon technology promise to open up new applications and opportunities in the tech world. As we look ahead, it’s clear that the humble silicon wafer will be a crucial building block in the next generation of electronic devices and systems.

To purchase Silicon Wafer, please follow the link.