Introduction

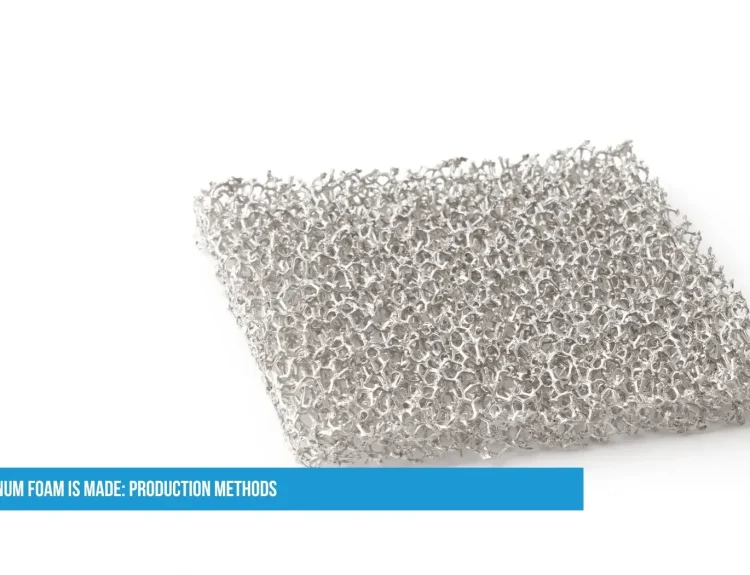

Nickel foam is a lightweight, sponge-like metal made mainly from nickel. Even though it looks like foam, it is actually solid metal with many tiny holes or pores. Because of its special structure, nickel foam is light, strong, and highly conductive, making it useful in many modern technologies, such as batteries, fuel cells, and catalysts.

What is Nickel Foam?

Nickel foam is a porous metal material, meaning it has a network of interconnected pores (tiny holes) throughout its structure. These pores can occupy more than 90% of its volume, making the foam much lighter than solid nickel.

- Good electrical conductivity

- High thermal conductivity

- Strong corrosion resistance

- Mechanical strength

- Because of these features, nickel foam is often used as a support material or electrode in energy storage and chemical applications.

How is Nickel Foam Made?

There are a few ways to make nickel foam, but the most common method is the foam replication method (also called the “template method”). Here’s how it works in simple steps:

Template Preparation

A piece of polyurethane (PU) foam—a type of plastic sponge—is used as a template. This foam has a 3D network similar to what we want in the final nickel foam.

Nickel Coating

- The PU foam is then coated with nickel. This can be done by:

- Electroplating: depositing nickel from a chemical solution using electricity.

- Chemical plating: nickel deposits onto the foam through a chemical reaction.

- The nickel layer forms around the plastic framework.

Template Removal

Once coated, the foam is heated in a special furnace (under a controlled atmosphere) to remove the PU template. The plastic burns away, leaving behind only the nickel structure.

Sintering

The remaining nickel structure is sintered (heated again at high temperature) to strengthen the metal bonds. This step makes the nickel foam more durable and stable.

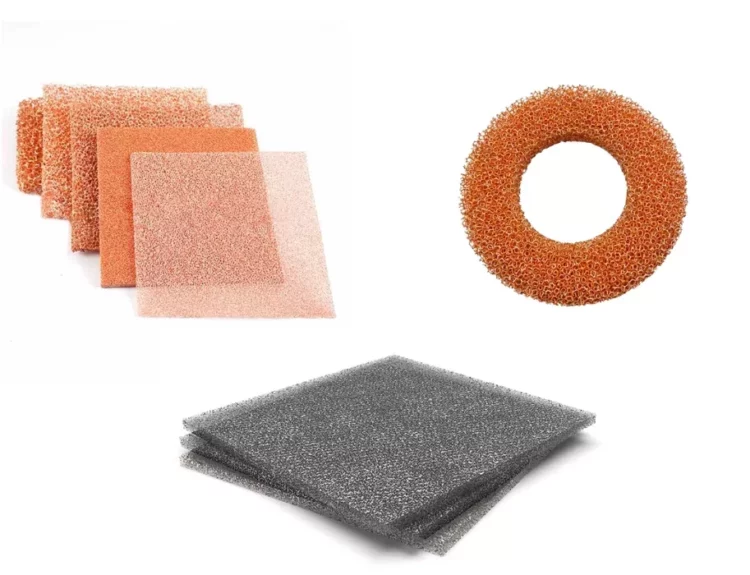

Types of Nickel Foam

There are generally two types:

Open-cell nickel foam: Has connected pores, allowing air or liquid to pass through. Commonly used in batteries and catalysts.

Closed-cell nickel foam: Pores are sealed. Used for sound and heat insulation.

Applications of Nickel Foam

Nickel foam has many uses across industries because of its unique combination of lightness, conductivity, and chemical resistance:

- Batteries and Supercapacitors – Used as a current collector in nickel–metal hydride (NiMH), lithium-ion, and other rechargeable batteries.

- Catalysts – The large surface area enables more chemical reactions, making it ideal for hydrogen production and environmental purification.

- Fuel Cells – Act as a support for electrodes that generate electricity from hydrogen and oxygen.

- Filtration and Absorption – Can filter liquids or gases and absorb sound or heat.

- Electromagnetic Shielding – Helps block unwanted electrical signals in electronic devices.

Conclusion

Nickel foam is a modern, high-performance material with a unique porous structure. It combines the best of both worlds: the strength and conductivity of metal and the lightweight nature of foam. Because of these properties, nickel foam plays a vital role in energy storage, catalysis, and electronic devices. It remains a key material in the development of clean, efficient technologies.